8 Reasons Why You Should Use

3D Printing for Jigs & Fixtures

Post By: Ryan King On: 23-03-2021 - Industry 4.0 - Industry Trends - Manufacturing

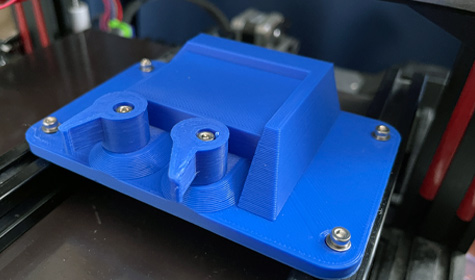

Jigs, grips and fixtures are used in manufacturing to ensure that component parts can be produced accurately over many cycles or iterations. The jig supports and holds a workpiece in place, while guiding a machining or cutting tool as it carries out a specific task. The fixtures and grips provide additional support and precise location for each part.

Jigs and fixtures are typically made from steel or aluminium, but the introduction of 3D printing, or more accurately, additive manufacturing, means a greater range of materials can be used. This process has been adopted most prominently in the automotive, defence, aerospace and rail industries. In this guide, we're going to outline eight reasons why you should use 3D printing for jigs and fixtures, including increases in speed and performance, and reductions in time and expenditure.

1. Cost Reduction

Time is money, and the reduction in time taken to produce parts by additive manufacturing rather than machining automatically saves you money. In addition, instead of outsourcing the machining of specialised jigs and fixtures, they can be printed in house. This saves both time and money paid to third-party suppliers.

With additive manufacturing, a 3D model is designed on a computer and sent electronically to your 3D printer. There, it's immediately analysed and printed automatically, requiring very little time or labour. Jigs and fixtures made in this way also use much cheaper materials, such as thermoplastics.

2. No Machining

3D printed jigs and fixtures can be produced very quickly, because of the way they’re designed and the materials used in additive manufacturing. To have such parts CNC machined frequently involves sending them out to a specialist in complex metal geometries. You need highly skilled CAM designers and a significant amount of planning, which extends lead times into days, and sometimes weeks. Additive manufacturing and design can largely be done in house, cutting lead times down to a day or less.

3. Customisation

Another reason why you should use 3D printing for jigs and fixtures is that you can design them to fit your own particular needs and circumstances. You can deploy much more complex geometries, and produce tools that would not be possible using traditional machining methods. You can also make your parts in a range of colours and surface finishes. Your engineers no longer need to design a tool purely for its manufacturability; they now have the ability to tailor the tool for the task or the operator.

3D printing takes advantage of a wide range of technologies and materials, and you can build in special properties such as heat and chemical resistance, UV stability and flame retardancy. This enables the design of strong, lightweight tools with high-performance materials, for complex and precise operations such as medical surgery.

Most of the materials used for additive manufacturing are lighter than aluminium, and are not printed as a solid but rather as a shell that is completed with infill. This further reduces the overall weight of parts, and consequently helps to increase productivity. Tools are less cumbersome and easier to move around the production floor. Materials like thermoplastics, rubber and wax can also be combined in 3D printing to create new materials with significantly greater mechanical properties. These can then be used to make stronger, lighter tooling parts.

4. Component Consolidation

One of the most compelling reasons why you should use 3D printing is the freedom of design that additive manufacturing allows. Tools can be much more complex, but you can also reduce or even eliminate altogether the long lead times, labour and costs that are required for assembly operations. Instead of multiple components being engineered for a tool requiring assembly and fitting, the whole thing can be redesigned as a single contiguous component. This will improve the overall precision and accuracy of the finished tool, while allowing no opportunity for failure of contributory parts.

5. Faster Iterations

Since 3D printing is based on 3D CAD models and a digital manufacturing process, you can do as many iterations as you like in a much faster time. Once you're satisfied with the CAD model, all you have to do is upload it to your 3D printer, and you could potentially get your part printed in a few hours. It takes so little time that, if you don't like the design or it has a flaw, you can keep optimising it through as many iterations as it needs to get it right.

The rapidity of these processes means that your designers have a great deal more freedom and time to optimise their design before it goes into full production. This may have a substantial impact on your ability to deliver product to your customers speedily on demand, thus improving your company standing.

6. Complex Design

3D printing makes it much simpler for you to come up with new and improved designs that will help your jigs and fixtures to deliver a better performance. To do this with tools produced by traditional methods would be a colossal task, requiring much more effort and expense to create new jigs and fixtures. With 3D printing, you can create new designs at regular intervals, optimised for performance and delivered with greater speed and less cost.

As your tool production will no longer be limited by machining or injection moulding operations, you have a much larger scope with 3D printing for tool configuration. This means you no longer have to worry about conventional design considerations, such as irregular contours or profiles, or the number of setups that will be required for your parts.

7. Digital Inventory

In a manufacturing context, digital inventory refers to a computerised file management system that provides you with virtual storage for your 3D designs. Storing parts virtually means that you can reduce your warehouse space, as you'll no longer need to maintain a significant physical inventory. You'll have instant access to your CAD models and design files, making your production abilities more immediate and agile. Another very compelling reason to use 3D printing for your jigs and fixtures is that you don't have to have a big production run. In fact, it's better suited to producing lower quantities on demand.

A further advantage is that you can replace obsolete components, by redesigning them for 3D printing and digital storage. Retrieving files when needed is fast and simple, with no heavy lifting required. Parts can even be produced in the location where they're actually going to be used, which has a great impact on logistics.

Once you install a 3D printer and digital inventory on your production floor, you'll be able to produce parts in house, and no longer need to move them around physically. This will not only speed up delivery, but also reduce your shipping volumes and transportation costs. This is particularly useful for any business that operates in extreme or remote locations, such as battlefields, oil rigs – or space stations!

8. Better Ergonomics

Jigs and fixtures have to be physically handled by people on the production floor, so reducing their weight using 3D printing can make them easier for workers to use. Designing tools with CAD modelling also means that you can incorporate organic shapes and contours, providing operators with greater comfort and improved accuracy. Jigs and fixtures with ergonomic functionality help to reduce both downtime and the number of flawed units, and are safer for operator health.

The Benefits Summarised

These are some of the many reasons why you should use 3D printing for jigs and fixtures. They can be summarised as cost, convenience, speed, safety and adaptability.

Get More From Rowse Straight To Your Inbox