5 Key Safety Functions in a Pneumatic System

Post By: Tom Rowse On: 03-04-2020 - Pneumatics - Safety

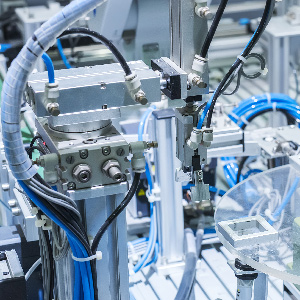

Machine building has become more complex with the introduction of more automated systems, and designers must devote more careful attention to the newer safety standards that apply. Mechanical safety standards had to be supplemented with new procedures for functional safety and performance reliability. In 2006, ISO 13849 was revised to incorporate safety functions for machine control systems, reflecting the move towards more software-based architecture.

Designers must anticipate every possible eventuality for the system, whether it is operational, not operating or being serviced. Incorporating standards like ISO 13849 will ensure the maximum possible safety of pneumatic circuits and components, based on risk assessment and performance level (PL) parameters. Using factors such as MTTFd (mean time to dangerous failure), CCF (common cause failures) and DC (diagnostic coverage), the PL can be calculated for each individual safety function, and a required level of performance stipulated (PLr).

5 Key Safety Functions in a Pneumatic System

When designing a pneumatic system, there are five key safety functions that must be considered.

1. Protection Against Unplanned Start-up

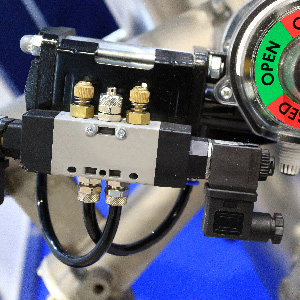

One of the most important safety functions in a pneumatic system, or indeed any automated system, is to protect against the machine starting up accidentally. The most common way to do this is with a pneumatic safety valve which has been built for the purpose, and certified to the appropriate PLr. For PLc a simple solenoid valve is sufficient, with a single valve element which will cut in. More sophisticated valve constructions are required for PLd or e applications, which will often need redundant valve elements to assure full safety functionality. Some products may have inbuilt electronics for this function, while others may require a safety PLC or external safe relay to comply with requirements for safety certification.

2. Exhaust or Air Pressure Dump Protection

Dumping or exhausting of air pressure will probably occur at the same time as an unexpected start-up, and many modern safety components combine the two functions. A pressure supply valve will shut off the air supply in the event of any failure, preventing excess air pressure building up in the system. At the same time, air pressure within the system will be dumped safely, although a manual exhaust release can also be installed as a back-up. In the two-channel, three-valve system that is commonly used with higher PL applications, the downstream flow will be greater than the input supply, so that downstream pressure can still be reduced to a safe level, even if the input valve fails to shut off. More recent technology is likely to incorporate soft-start valves and position sensors to control unexpected start-ups and pressure dumps.

3. Holding, Blocking and Stopping

Holding, blocking or stopping operational equipment is one of the key safety functions in a pneumatic system, and applies to all kinds of applications across a wide PL range. It may be as simple as installing a pressure-operated check valve in the cylinder port. The trapped air pressure in the cylinder will hold the load and make sure it can't move, and a pressure switch added to the circuit could provide DC.

In more complex applications requiring higher PL, a mechanical lock or brake may be installed on the cylinder's piston rod. This clamps the piston rod into position using spring pressure and an appropriate valve. Another version of the rod lock comprises a pneumatic device installed on the piston rod. This device only allows cylinder movement if air pressure is directed to a port on the rod lock itself. Increased DC can be obtained by adding a sensor to detect when the rod lock is engaged.

4. Reversing Cylinder Movement

In simple, low PL applications, this safety function can be accomplished in a pneumatic system by a spring-return solenoid valve. Higher PL applications will require a more robust solution, such as a servo-pneumatic unit. The safety functionality in category 4 control architecture relies on the position of each valve element being sensed and transmitted to a safety PLC. This will ensure that the cylinder may only extend if both valve elements have moved.

5. Reducing Speed

Reducing speed is the easiest to implement of the key safety functions in a pneumatic system. It requires the installation of simple flow controls that can be validated with the appropriate movement parameters. Tamper-resistant locks may be installed to ensure these parameters are not altered.

Get More From Rowse Straight To Your Inbox