ABB Jokab Safety

Kungsbacka, Sweden Trip

Post By: Ryan King On: 18-10-2019 - Automation & Control - Company Updates - Safety

Rowse has recently returned from Sweden after being invited by ABB to undertake their ABB Jokab Safety partner training. The training had been developed for ABB Machine Safety partners to provide them with a much deeper technical knowledge of their machine safety products and consisted of mainly of hands-on exercises as well as some open discussions and training on Machine Safety practices across throughout Europe.

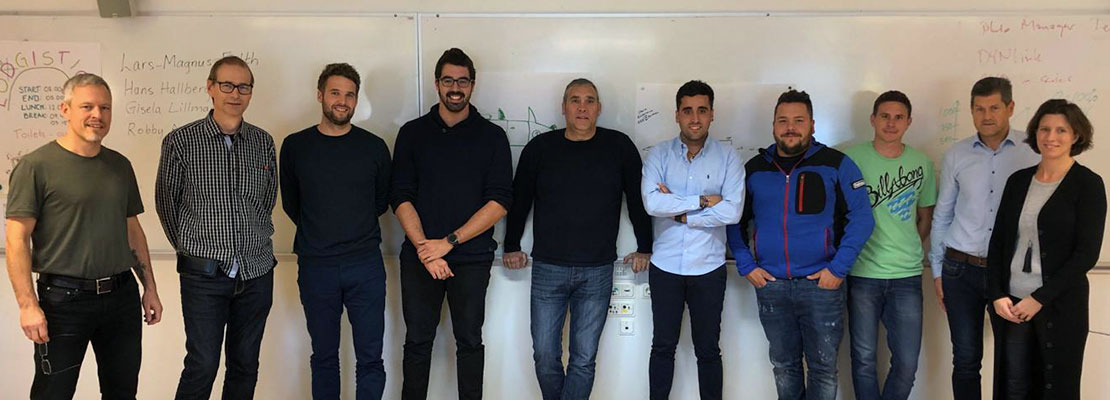

Rowse was invited by Mathew Swan and Shane White of ABB GB to participate in the week-long course that was held Kungsbacka, Sweden. Shane White is the Product Marketing Manager of ABB Jokab in the United Kingdom and Mathew Swan their Safety Specialist. Mathew would also accompany Rowse throughout the trip. Representing Rowse was our Machine Safety Specialist Tom Rowse, CMSE®. Rowse was extremely honoured to be the only company representing ABB Safety Partner Network in the United Kingdom. Also attending was representatives of the ABB Spain, Germany, Austria and Sweden.

"The opportunity to go to ABB Jokab for in-depth product training on their products was an opportunity I could not say no to. I have been on many different training courses put together by manufacturers; however from the offset, I knew this training would be different. We were provided with online training that needed to be completed before the visit, just by completing this training I knew this course would be different from the others I have completed previously. The knowledge and passion each of the trainers had for machine safety was infectious, knowing ABB has these safety experts backing up their product is very reassuring. The whole trip was fantastic, as well as learning about the ABB portfolio and machine standards, I made some great friends from other ABB countries."

Tom Rowse, CMSE

ABB Jokab Kungsbacka

The training course had been developed by the ABB Jokab Kungsbacka Technical Support team, as well as having to undertake the on-site training, a comprehensive range of online training had to be completed to ensure all participants had the required level of knowledge to complete the on-site training in Sweden.

ABB’s Technical Support team that would be training the participants included:

- Lars-Magnus Felth – Tech support manager

- Hans Hallberg – Tech support

- Robby Andersson – Tech support

- Gisela Lillman – Tech support

- Mikael Sjövall – Fence (not in picture)

ABB Jokab Product Training

The training focussed on a few key ranges of the ABB Jokab range, with an emphasis on practical use and working demo’s. The key areas that we looked training centred on the following products:

- ABB Orion Light Guards

- ABB Vital Safety Controller

- ABB Sentry Safety Relays

- ABB Pluto Programmable Safety Controller

- ABB Safety Fencing Systems

- Functional Safety Standards

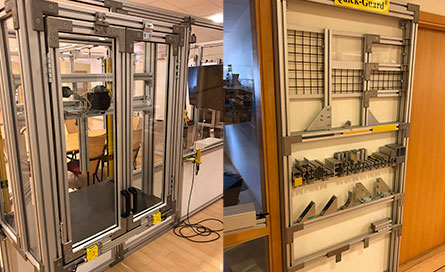

The training started initially with the ABB Jokab Safety Fencing Range, and the training was presented by Mikael Sjövall. The trainees were introduced to the two types of Safety Fencing available from ABB Quick-Guard and Quick-Guard Express. The Quick-Guard Express fencing system

ABB Jokab Safety Fencing

The first area of focus was the Jokab Safety Fencing, the range is known as Quick-Guard and there are two different types; Quick-Guard and Quick-Guard Express. Quick-Guard Express is a type of safety fencing designed for a quick install on-site and is very cost-effective. A complete safety fencing system can be quickly erected with minimal components, the range consists of fence posts, welded mesh, infill panels of polycarbonate, brackets and pre-assembled doors. The benefits of using the ABB Quick-Guard Express range are:

- Fast Installation

- Light Weight

- Highly adaptable with minimal maintenance needs

- Esthetically appealing

The alternative of Quick-Guard Express is the standard Quick-Guard. With Quick-Guard fencing, you can provide a simple sketch or AutoCAD file of the proposed fencing system and ABB Jokab using their SafeCAD system can design the fence in 3D. The fence can then be supplied in cut to length ready for installation.

The benefits of using the ABB Jokab Quick-Guard range are:

- Light and robust aluminium profiles

- Wide selection of materials for panels

- Cut to size according to drawing

- No drilling, no welding

ABB Jokab Sentry Safety Relays

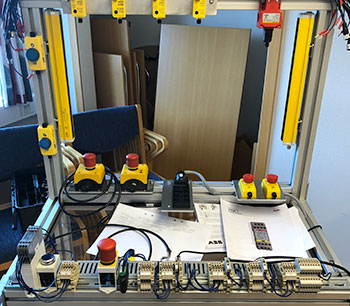

The training then introduced the trainees to the ABB Jokab range of Safety Relays. ABB Jokab has some of the most flexible safety relays currently available, and they developed their first universal relay back in 1988. The latest safety relays from ABB consist of four different families for varying applications.

Each trainee was provided with a training rig fitted with a safety relay from each of the Sentry families. Each safety relay needed to connect up a simple safety circuit utilising the ABB Smile 11 EA Emergency Stop Button, Smile 11RA Reset Button, ABB Contactors and a simple fan to simulate a motor.

Starting with the ABB Sentry BSR which is the entry-level safety relay for basic applications such as monitoring of emergency stop buttons and the expansion of safety outputs when no timer function is needed. The safety circuit had to be connected and configured to stop the fan when the emergency stop was pressed, once the emergency stop button had been reset the safety circuit would require a manual reset by pressing the Smile 11RA Reset Button.

The trainees then moved onto the ABB Sentry SSR models, these models are designed for specific applications such as 1 and 2 channel devices, OSSD devices and two-hand devices. As with the BSR Safety Relays the SSR range are easy to configure and specify, some of the SSR relays even come with an off-delay function. Once again the same safety functions were used along with the introduction of an Eden OSSD non-contact safety switch for the monitoring of a simple hatch on the demo rig. If a longer off-delay was required or further timer functions required ABB have their Sentry TSR, the TSR Safety Relay can also be used as an expansion relay with timer functions.

ABB Sentry USR was the last safety relay that needed to be configured. ABB Sentry USR is the latest incarnation of ABBs universal safety relay. A universal safety relay can be used with multiple safety devices they are configurable for each application and thanks to a handy front display can offer error tracing. The USR relay had to be configured to monitor a ABB Safety Edge for the switching of the same fan circuit.

Everyone was impressed by the simplicity and functionality of the ABB Jokab Sentry Safety Relays, some of the highlights were:

- Up to PL e/SIL3

- Lighting and flashing of the reset button managed by the Sentry safety relay

- Extensive LED indication

- Removable terminal blocks

- Powerful outputs, up to 6A

- Simple expansion of Pluto safe transistor outputs (BSR models)

- Manual or automatic reset selectable by switch on front (SSR models)

- Display on front for configuration and error tracing (TSR10 and USR models)

- Advanced timer functions (TSR10 and USR models)

- Multi-reset allows one reset button to reset up to 10 safety relays (+24 VDC models with manual reset function)

ABB Jokab Pluto Programmable Safety Controller

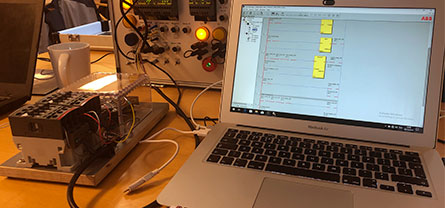

ABB Pluto is a cost-effective, powerful and compact safety PLC that can be used in all machine safety applications. Pluto can connect directly to most safety devices on the market, due to the design of the Pluto multiple safety sensors can be connected to a single input still achieving the highest safety level.

Programming the Pluto is carried out using the Pluto Manager Software which is a free download from the ABB website. As a prerequisite of the training, each trainee had carried out online training using the Pluto Manager Software, this training is available free of charge to ABB customers and is a great introduction for anyone new to the ABB Pluto range.

As the trainees had a good base knowledge of the Pluto range the training consisted of communication between different Pluto models using the integrated StatusBus, Gateway Communication to other communication devices and utilising encoders in a safety system.

Once again training test rigs were provided to each of the trainees, the training rigs consisted of two different ABB Pluto Safety PLCs that were communicating on the StatusBus, a number of digital and analogue inputs, LED indicator lamps for the outputs, safety devices such as emergency stops and Eden OSSD switches and some contactors controlling a simple fan.

Each trainee was required to carry out several programming tasks which were then downloaded to the Pluto PLc’s for testing by the ABB Jokab instructors. Each task fed into the next task with the result ending in a complex safety system configured on the Pluto Manager Software and being demonstrated on the training rig.

ABB Pluto is available in a number of different models, from simple models for small systems and bigger models for more complex systems. Some of the Pluto models are also equipped with As-i communication.

Everyone was in agreement that the ABB Pluto Safety PLC is a very powerful device with endless possibilities, some of the main benefits are:

- Easy programming and still powerful

- Most Machine Safety functions inclusive speed monitoring and analog input monitoring

- Eliminates the need for extra module for speed monitoring for ex.

- Up to 32 Pluto can exchange data without extra programming

- Safe bus simplifies the connection between cabinets in accordance with PL e/SIL3

- AS-i models simplify connection

- Extensive communication possibilities with HMI and PLCs

- Advanced programming possibilities

- Ladder and TÜV approved function blocks

- PL e/SIL 3

ABB Jokab Orion Safety Light Curtains

The final area of training involved the ABB Orion Light Curtains. The Orion range of Safety Light Curtains is an optical safety device that detects a presence in their protected field, unlike an emergency stop, they do not need any action to operate from the machine operator.

ABB Jokab has three families of Safety Light Curtains; Orion 1, Orion 2 and Orion 3. Within each family there is a model classed as the base model and an extended version. In addition to the standard features of the base model, extended Orion light curtains have more functionality including; muting, blanking and also cascading blanking. Within each Orion family, different resolutions are available depending upon the application, from 14mm up to 30mm for Orion 1 and 2, Orion 3 is available with 2,3 or 4 beams.

The training for the Orion light curtain involved several different workstations for setting up various light curtain applications. Each trainee was required to set up and configure these applications before the trainer would test them. The skills to be developed were:

- Installing A Local Reset Button - Usually a reset button is connected to the safety control module (safety relay, safety PLC), on the Orion light curtains a local reset button can be connected directly to the light guard saving safety relays/programmable inputs and minimizing cabling to the electrical cabinet.

- Blanking Function - The blanking function allows users to define a number of beams that can be constantly interrupted without stopping the machine. In this way a fixed material or a cable is allowed in the protected field, but a hand interrupting an extra beam would stop the machine.

- Floating blanking – As with the blanking function several predetermined beams can be broken without stopping blanking, with floating blanking, however, the object can move within the protected field. An example of this could be a cable being reeled onto a cable drum.

- Muting - Using external muting sensors to the light guard, the light curtain can distinguish between material and persons entering the safety field. Muting functions are often used on conveyor systems were a pallet may be passing into the danger zone for processing or leaving the danger zone.

With relatively little experience in setting and configuring light curtains, each of the trainees was able to successfully set up the Orion Systems. Each system also used a number of other ABB Jokab products such as Safety Relays, Vital Safety Controllers, Smile 11RA Reset Buttons and Smile 11EA Emergency Stop Buttons.

Everyone was impressed by the Orion Light curtains in particular:

- Easy to use - no more functions or settings than necessary.

- A local reset button can be connected directly to the light curtain: no need for cable between the reset button and the electrical cabinet or for an extra control module.

- M12 connection

- Muting sensors are connected directly to the light grid, with no need for a remote muting module.

- Alignment help facilitates alignment with rotation brackets to simplify alignment

- Extensive error indication reduces troubleshooting time.

- Type 4

ABB Jokab Safety Trip Overview

Rowse was very fortunate to be invited to the ABB Jokab Factory it was a fantastic opportunity to visit the ABB Factory and explore Sweden. Having a broad range of nationalities representing different ABB locations was also really interesting. Especially when talking about their local markets and business segments with differing business and technical challenges that each of us face.

Rowse would like to extend their thanks to all the ABB staff at the Kungsbacka Factory, special thanks must go to the trainers; Lars-Magnus Felth, Hans Hallberg, Robby Andersson, Gisela Lillman and Mikael Sjövall. It was the most comprehensive manufacturers training that we have attended and was a great benefit to Rowse and also our customers. Special thanks must also be extended to ABB GB to Mathew Swan and Shane White for the invitation in the first place.

Get More From Rowse Straight To Your Inbox