An Introduction To Digital Twins

Post By: Ryan King On: 13-12-2019 - Industry 4.0 - Industry Trends

Digital Twins are the latest crystallisation of the technology advances loosely connected under the umbrella of Industry 4.0 and the IoT. This digital representation technology enhances the already strong links that tie the digital world to reality, and provides an even closer representation of how things work than 3D simulations. Digital-twinning is a holistic approach to the many and varied processes that go into modern industry, and demands a quantum shift in production culture.

What Are Digital Twins?

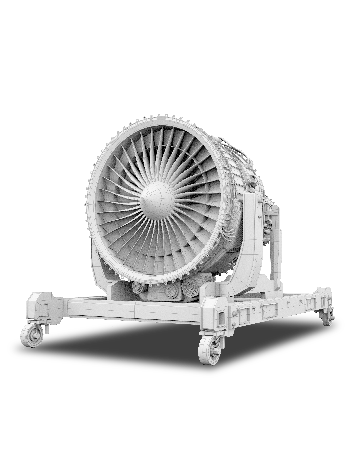

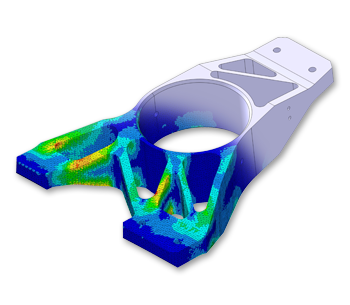

Digital twins are a complex conglomerate of technical data, combined to make a virtual technological representation of a physical process or product. They simulate a product's entire life cycle, predicting its behaviour, and optimising its design and production system. They incorporate AI and machine learning capabilities, data analytics and multi-physics simulations. They demonstrate the potential impact of environmental or usage conditions, design changes and many performance variables. Digital twins are a cost-effective means of understanding the performance characteristics of a real-world physical counterpart, before any investment is made in actual prototypes. This cuts down drastically on development time, and delivers a final process or product of optimal quality.

Obviously, it's necessary to use physical objects as the paradigm for digital twinning, in order to ensure that the technical modelling is accurate. This takes place over a product's entire lifetime or production cycle, using data gathered from sensors installed on such objects. This data will reflect real-time performance of the modelled object or process, including its operating conditions and any alterations in performance that occur over time. The digital twin continuously updates the model during its life cycle, constantly evolving to create a virtual feedback loop.

Digital Twins Use Cases

Digital twins generally fall into three categories of asset modelling. These are combined and integrated into a digital thread which permeates the entire fabric of the asset's life cycle.

Product digital twins consist of a virtual link to a model product that demonstrates how it performs in various operating conditions, obviating the necessity for multiple physical prototypes. Product digital twins also improve the manufactured product's final quality, and provide a much faster and more effective response to feedback.

Production digital twins simulate production processes, analysing and validating what is happening and why, so as to create a more streamlined production methodology that can be optimised for different conditions. Sensory data can be used for predictive maintenance, making manufacturing operations faster, more reliable, and ultimately more efficient.

Performance digital twins capture huge amounts of operational data in a product's performance, analysing it with big data analytics and acting on the information to enable more informed decision-making.

Digital Twins Vs Simulations

Advanced 3D simulations are definitely an integral part of the new technology, but digital twinning goes far beyond that. Digital twins are a comprehensive concept incorporating multiple other technologies, including AI, the IoT, big data, edge computing and much more. All these combine together to construct a digital equivalent of a physical asset or entity, as an accessible 3D visual simulation. This allows human operators to monitor, analyse and respond to real time situations.

Simulations in the past helped designers to understand what could possibly happen to a product's performance in the real world, without being able to affect it. Digital twins examine the entire product life cycle, helping designers to understand not only what might happen to it in performance, but what is happening to it live.

Digital Twins In The Rail Industry

Digital twins incorporate the actual running of an existing rail network, enabling engineers to examine every step of the process as well as the equipment itself. With these networks still needing a lot of overhaul, the process must be cumulative, with a vast amount of different data needing to be coherently amalgamated.

Some operators want to use digital twins to provide full visibility of information throughout the design cycle, so that end users may have early design inputs to infrastructure, assets and projects. Digital twinning combined with augmented reality software would supply real-time asset simulations with live data. This thread could also incorporate predictive models of various system interventions, taking social outcomes into account to improve decision making. Digital twins allow real time changes to be recorded across networks, demonstrating the impact of human and environmental changes. They could be used to map out potential escape routes and human traffic behaviours in the event of a disaster.

Digital Twins In The Military

Military platforms in all domains function on multiple advanced technologies, such as communications and IT networks, command and control systems, surveillance, weapons systems, and much more. Design engineers must also integrate multiple different systems built by different manufacturers for many different purposes, with equipment becoming ever more complex and technologically advanced. Performance testing in varying conditions can be carried out using digital twins. This will help predict the platform's interoperability and integration issues, as well as scheduling maintenance and any necessary retrofitting.

Leaders want expensive fleets to last longer, but also to stay up-to-date with the changing demands of a service life that may extend for 50 years. Upgrades and retro-fitting are inevitable, and digital twins offer the opportunity to test and optimise designs before any expensive installation takes place. The functioning of complex systems and high grade materials can also be realistically simulated, to explore their performance range and the impact of changing roles. In extreme circumstances, digital twins could provide experts at base operations the means to help resolve problems down range.

The US military is already exploring digital twins with the IoT to see how all aspects of military ops can be connected, covering the whole cycle – from initiation, through maintenance, to eventual retirement. This holistic approach includes not only the fabric and systems of equipment, but troop movements, soldiers' uniforms, and their health status. Constant data input from surveillance and other assets provides real-time insights into potential threats, including movements of enemy troops and vessels, so that more informed decisions can be made.

Digital Twin Tech And The Future

Many branches of industry are now looking into digital twins as the future of testing, control and managing complex systems, where all problems can be resolved before any substantial time or money is invested in physical production. Adopting digital twin technology involves much closer communication between designers, engineers, managers and end-users, but the increased investment in planning is far less costly in time and money than physically modifying an existing product.

Get More From Rowse Straight To Your Inbox