Five Key Concepts

in Automation

Post By: Tom Rowse On: 15-08-2018 - Automation & Control

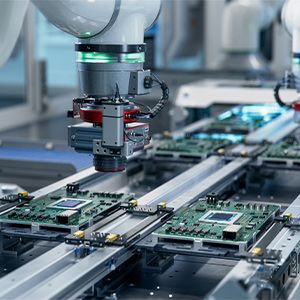

Automation concepts cover a range of increasingly complex machine initiatives that enhance all areas of 21st century life, and are especially useful for streamlining commercial and production processes.

Programmable Logic Controller (PLC)

A PLC is designed to control part or all of a manufacturing process, and is simple to use and set up, even for entry level programmers. A PLC can diagnose faults quickly, and its modular design allows for tailor-made systems to suit every application. A PLC is a highly reliable industrial computer, constructed from high grade, durable materials that can withstand a range of environmental pressures. Its real time response to changing conditions means operations continue uninterrupted, even while a fault is being resolved.

Human Machine Interface (HMI)

An HMI is what enables human interaction with the machines that are doing the work, and usually consists of a panel interface that may have keypads, displays and USB connections. While human beings control and operate the machine via the HMI, the machine closely monitors production, and simultaneously feeds back information to the operator. This allows quicker and more accurate decision-making, and a rapid response to constantly changing production demands.

Distributed Control System (DCS)

A Distributed Control System is one where a network of autonomous machine controllers is centrally governed by a supervisory operator. Various nodes and control processors are placed at strategic points throughout the manufacturing system, where they can assist in batch-orientated or continuous processes. This means that any problems in the system are localised, and only affect that part of the manufacturing process directly controlled by the node, thus reducing overall production downtime.

Supervisory Control and Data Acquisition (SCADA)

SCADA is a more complex automation concept, referring to a control system architecture which provides an advanced level of supervisory plant management. This architecture comprises a whole network of computers, in one or more locations, combined with a user interface and high speed data communications which allow a distributed network to be accessed remotely.

Artificial Neural Network (ANN)

An ANN is the basis of Artificial Intelligence, and is effectively a computer model based on a biological brain. The brain's neural structure comprises a network of interconnected sensors and synapses, which receive and transmit information to a biological creature and control its responses to received sensory data. The big advantage of a neural network is that it learns, by processing and adapting both internal and external information, and an ANN does this in the same way as a biological one. ANNs process data sets and learn from the information there, so that they can respond to problems and produce solutions from their own computational capacity.

Visit our dedicated Rowse Automation site for more information and products.

Get More From Rowse Straight To Your Inbox