Manufacturing A Circular Economy

Post By: Ryan King On: 09-07-2021 - Industry Trends - Manufacturing

The threats to our climate and our global subsistence are beginning to impact industry, in a shift that brings recycling more directly into the manufacturing environment. It's widely recognised that something serious needs to be done to conserve the world's resources.

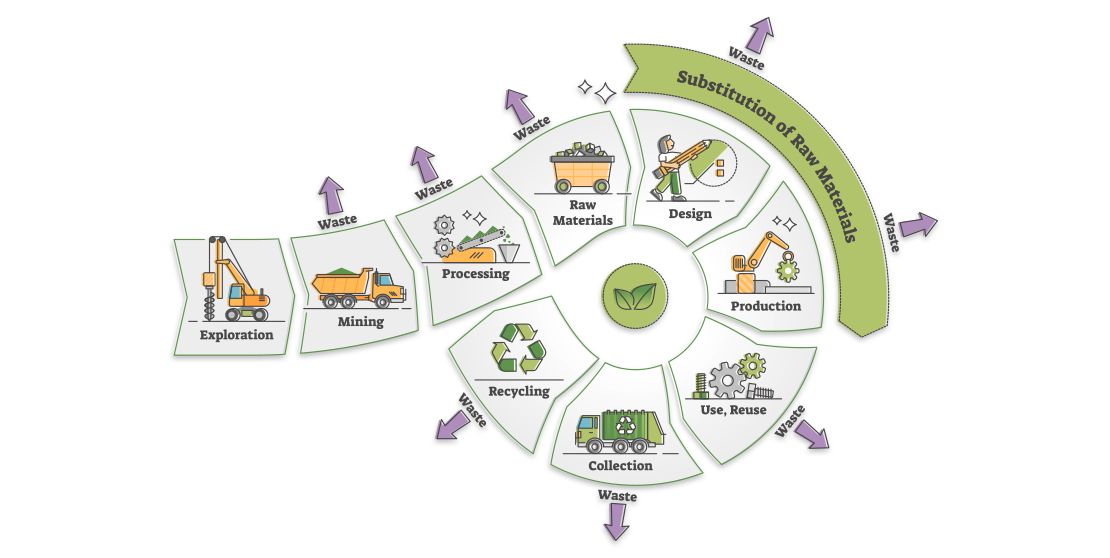

A circular economy is a system that incorporates the principles of recycling into the manufacturing process. With our eyes on a net-zero emissions target, and a greener future for our planet, we're looking to promote sustainability in industry in a way that’s still competitive for business.

What Is A Circular Economy?

A circular economy is the direct opposite of our previous modes of consumption, which were for many years directed at single-use, disposable products. Little thought was given to the amount of irreplaceable global resources used in manufacturing, or the amount of waste produced, both during the manufacturing process and in disposing of the end product at the end of its life cycle.

The problem is exacerbated by the type and amount of waste we produce, since a lot of it is non-natural material that doesn't decompose. Raw materials have not been used carefully enough in the past, so that unnecessary waste has been produced during the manufacturing process as well as when products were finally thrown out. Our solution has been to bury all this non-recyclable waste, or to ship it offshore for disposal, but this leads only to further environmental problems. These include plastic mountains, excess greenhouse gases and, ultimately, severely damaged ecosystems.

It also costs money. Excess waste generation during manufacturing indicates an overuse of raw resources, while disposing of waste can cost a company between 4 and 10% of their typical annual turnover. At the moment, this includes a landfill tax of £96.70 per tonne in the UK, plus waste preparation and transportation costs.

A circular economy alters this linear consumer model of "take-make-scrap". It directs production and consumption into a circular model of repair and reuse, sharing and remanufacture of materials, plus recycling at all levels. It reduces the demand for raw materials, helps to extend product life, and reduces end-of-life cycle waste.

This is nothing new, historically; before the age of conspicuous consumption, the ideal product was built to last. Today we have to revisit the old principles to extend product life cycles as much as possible and reduce as much waste as we can. In industry, this process starts right at the beginning, by designing value-added products. Adding value to a product can take many forms, such as cutting down its material content or making items easier to dismantle and repurpose.

What Are The Benefits Of A Circular Economy?

The benefits of a circular economy embrace many aspects of our manufacturing future, as we strive to achieve greener practices in industry and a target of net-zero emissions by 2050. These include:

1. Better Business Models

Manufacturers will be seeking to reduce waste in the production process and remanufacture products from reused materials. Even during a transition phase, some estimates suggest that European (including UK) manufacturers could save several billions in material costs as the circular economy is phased in. Several companies are already researching flexible remanufacturing models, and finding out how to be proactive in disassembling used products for the most efficient recovery of materials.

Major corporations such as Heineken, Philips and Renault are leading the trend in manufacturing, focusing first on a reduction in irreplaceable core materials. They're also cutting down on energy usage, and reusing or recycling as much as possible from their end products.

2. Product Design Innovation Incentives

Businesses can develop their own industry-specific solutions to a circular economy, with design innovations including more sustainable packaging and waste reduction. New business opportunities are already emerging, as companies deploy more advanced technologies to recover and reuse raw materials. Initiatives include collecting plastic waste for reprocessing and making it into new packaging, thus reducing the total amount of scrapped plastic that would otherwise be sent to a landfill.

3. Continued Economic Growth And Job Creation

Some estimates suggest an increase in global productivity from reusable source materials of 30% or more. Under its Green New Deal policy, the EU has published a Circular Economy Action Plan, which projects a 0.8% increase in GDP consequent upon such a rise in productivity. A 0.8% rise in GDP could lead to two million new jobs being created in the next 10 years.

4. Direct Cost Benefits

Rapid-turnover consumer goods could recoup and reuse up to 20% of their original materials, saving on the production cost of new items. Waste disposal expenses will also be lower, together with savings on energy consumption as old materials are reused rather than machined from scratch.

5. Greater Energy Conservation

The overall demand for energy should be reduced, as industry adopts more renewable energy sources and works towards the elimination of carbon emissions.

6. Better Risk Management

Manufacturers that manage waste more efficiently may be less vulnerable to fluctuations in availability and input prices, despite constraints on raw material resources. The demand on core resources such as iron ore, for example, could be reduced by 110-170 million metric tonnes per year, if a 25% reclamation of used material is achieved. If the demand for raw iron ore were reduced to such an extent, the price would become much less volatile and risks could be better managed.

7. Increased Competitiveness

Companies who produce and promote built-to-last products and sustainable business practices will have a stronger competitive edge, potentially amounting to much greater value for money in their offering over those of competitors.

Restructuring To Meet Targets

Reducing our harmful environmental impact doesn't necessarily mean a loss of profits, but rather a restructuring of our business vision and goals to incorporate the principles of a circular economy.

Industry itself must be decarbonised, replacing fossil fuels with cleaner energy and reducing the amount of energy demanded by production processes. This will require a substantial initial investment, with probable retooling and retrofitting of equipment to run on clean energy sources. But it will pay off in the long run, as we begin to create more environmentally friendly products, and develop new business models that help the world achieve its zero emissions target.

Get More From Rowse Straight To Your Inbox