The Future of Pneumatics

Post By: Tom Rowse On: 01-07-2019 - Industry 4.0 - Industry Trends - Pneumatics

As the Fourth Industrial Revolution continues to change the face of the manufacturing world, many are questioning the future of pneumatics. We already have an inkling of how AI and machine learning are revolutionising traditional processes, from supply chain to product configuration. The IIoT enables a more advanced level of customisation, of precision engineering, and of quality management and risk assessment, with an integrated and programmable chain of activities from inception to conclusion. Add to this enhanced cloud connectivity, data analytics and decentralised edge computing, and we are already seeing a fundamental shift in design, build, operation and maintenance of industrial equipment and plant.

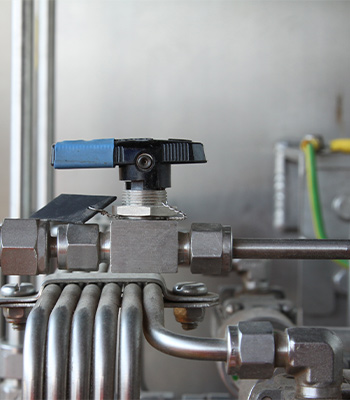

Statistics collected by the British Fluid Power Association show that sales of pneumatic equipment have actually increased to over £1.1 billion per annum over the past few years. Pneumatics manufacturers have played a considerable role in innovating and adapting systems to Industry 4.0, with industry leaders such as Festo and Camozzi introducing IIoT-compatible components to enhance the performance of their pneumatic actuators. Cost-efficient sensory and data processing tools are now forming an integral part of much fluid power equipment, from hoses, tubing and connectors to pneumatic drives, cylinders, filters and valves. Continuous position sensors, for instance, can determine the linear position of a pneumatic actuator's magnetic piston in its cylinder, with a contactless, high-resolution technology situated along the length of the sensor.

Smart Pneumatics

With sensory information flowing in both directions, old pneumatic processes are being transformed into smart pneumatic systems, with data communicated to higher-level controllers and distributed to local networks. Continuous position sensors provide an invaluable support to process control and optimisation, particularly in applications where consistent high quality, speed and replication are essential. Position sensors are also ideal for long-term deployment in challenging environments, as they can be upgraded with custom enhancements such as resistance to vibration, shock, chemical exposure, and water ingress.

Pneumatics is already the system of choice for many such applications, as its rugged nature enables it to withstand many extremes of temperature, pressure, and extreme environments. Material properties today are now so much improved, and production techniques so much enhanced, that high-volume manufacturing is increasing across the industry. This is helping to improve overall quality and reliability, while also reducing the costs of core components, such as pneumatic valves and cylinders. No other technology is capable of operating in such diverse conditions, making pneumatics the obvious choice for repetitive, high-volume, 'fit and forget' applications.

One of the key concepts driving the future of pneumatics is overall equipment effectiveness, which is improved with our enhanced understanding of machine systems and processes. While the focus is very much on the electronic and digital control of automated systems, this doesn't necessarily preclude a future for pneumatics, as many material elements of the pneumatic system are able to adapt their designs and processes to incorporate IIoT factors into their operation.

Lower Downtime, Lower Costs

Even five years ago (a long time in tech terms), an internet study reported that predictive maintenance could reduce costs by as much as 30%, with a corresponding reduction of equipment downtime of up to 70%. With Industry 4.0, this long-term industry goal is finally coming into view. For example, valve terminals are already in use with embedded intelligence which continuously monitors various operational factors, and generates data for diagnostic purposes. These factors include the number of run-time hours and switching operations, the condition of the power supply, and more. Pressure, position and flow sensors, designed and equipped with IO-Link capabilities, can deliver advanced data diagnostics and hot-swap capacity, giving manufacturers the ability to predict specific component failures and replacement schedules.

Many critics of pneumatic systems in the past have claimed that the costs of compressed air and the expenses of the overall life cycle of pneumatic equipment are detrimental to its economic viability. Pneumatics manufacturers have responded by developing best engineering practices and more efficient product designs, in order to achieve an increased efficiency in the use of compressed air. Festo, for instance, have developed an energy efficiency module, which has the capacity to monitor the operational condition of the machine, and automatically shut off the compressed air flow when it is in idle or standby mode. In addition to saving energy with this function, the Festo unit also monitors potential leaks, and supplies live data on air pressure, flow and consumption. This mass of streamed data is then sent via comm links to an industrial network connection for live management control, or into the Cloud so that end users can analyse it in the longer term.

Research & The Future of Pneumatics

Research projects are also in progress, combining the expertise of industry leaders and academics in order to develop new kinds of sensor technology. This research is looking at advanced electronic data collection systems; for example, using thin foils. These foils could be attached as labels to a pneumatic cylinder, where they would gather usage and sensory data and transmit it wirelessly to a control network. A combination of labels in a unit would produce a variety of simultaneously monitored drive data, and might also generate dynamic energy via the piston movement.

Industry leaders are also responding to the criticism of pneumatics as a more static and less responsive actuating system than electric drive technology, as the new Festo motion terminal has proved. A combination of piezo-electrically controlled valves and programmable motion apps allows this innovative motion terminal to change its valve functions in a similar way to an electric drive. This means that the motion terminal can customise its parameters to suit any particular type of product, with programmable stroke lengths and cylinder travel times. Connection to a distributed network further ensures that control functions and diagnostic reporting are live and simultaneous.

With today's technology, machines can be autonomously configured and continuously optimised, driving up equipment availability, quality and overall performance. Network-enabled devices provide integral sensory diagnostics, including component level data as well as production environment characteristics. Using a performance model of a device compared to a manufacturer’s own test data, management teams can predict the device's life expectancy under its actual operating conditions. When used properly, this data will revolutionise the way manufacturers operate and maintain pneumatic equipment, enabling continuous adjustment and fine-tuning in response to detailed sensory feedback.

Get More From Rowse Straight To Your Inbox