What Is Intelligent Supply Chain Management?

Post By: Luke West On: 08-06-2022

Digital transformation and the Industrial Internet of Things (IIoT) continue to impact industry at all levels. While it's seen its earliest adoption in large-scale manufacturing and transport, it's spreading rapidly into other sectors. One of the many process areas in which digital transformation delivers the most benefits is intelligent supply chain (ISC) management.

How Does Intelligent Supply Chain Management Work?

Applying artificial intelligence (AI) to the traditional structure of a supply chain accomplishes several things:

- Continuous monitoring of changes in supply and demand

- Anticipation of supply chain disruptions and informed correction

- Optimising available opportunities so as to deliver on time

- Much faster reactions to the ever-changing priorities of customers

In the simplest terms, an ISC uses the tools of IIoT to optimise decision-making in every potential circumstance. This helps you to save on costs, increase customer satisfaction, increase profitability, and ultimately, get ahead of your competition.

An organisation uses its connected network of devices and sensors continuously to collect data from sources like manufacturing, inventory, logistics and distribution. There are also external influences such as point-of-sale figures, real-time market information, business trends and weather data. Once this huge flow of raw data is aggregated into what's called big data, AI tools are applied to the datasets. Predictive analytics and machine learning (ML) then produce actionable insights, which you can use to make faster, more accurate business decisions.

In the simplest terms, an ISC uses the tools of IIoT to optimise decision-making in every potential circumstance. This helps you to save on costs, increase customer satisfaction, increase profitability, and ultimately, get ahead of your competition.

An organisation uses its connected network of devices and sensors continuously to collect data from sources like manufacturing, inventory, logistics and distribution. There are also external influences such as point-of-sale figures, real-time market information, business trends and weather data. Once this huge flow of raw data is aggregated into what's called big data, AI tools are applied to the datasets. Predictive analytics and machine learning (ML) then produce actionable insights, which you can use to make faster, more accurate business decisions.

Key Areas Of Adoption

If you decide to opt into intelligent supply chain management, you'll find lots of software solutions providing a raft of benefits. The most useful of these in improving your overall operations include the following.

1. Real-Time Collaboration

Implementing ISC management enables you to collaborate in real-time with multiple partners. Working as a combined organisation can help cut costs for all participants in your network. This comes both through bulk purchasing and distribution, and in improved planning strategies and execution. You can collaborate with suppliers, manufacturers and carriers, as well as with service providers. Shared activities might include calculating capacity availability, forecasting, inventory and purchase orders. You will improve your quality control and reduce traditional supply chain risks, optimising freight movements and carrier management.

2. Predictive Analytics

An ISC isn't going to give you control over the weather or other external factors, but it does make you more proactive. Predictive logistics updates will enhance your preparedness for traffic jams on a delivery route, as well as potential global disruptions like COVID-19. Plus, you’ll be able to come up with new strategies for optimisation that take in not only the supply chain, but all other aspects of your business. These kinds of insights can also contribute to reducing machine downtime, which in turn will optimise workflows and ensure the maximum efficiency of your operations.

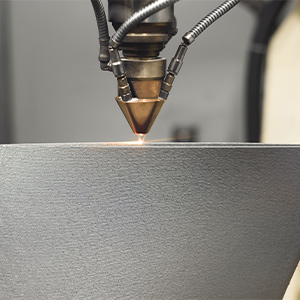

For example, predictive analytics can give you the edge in tackling future disruptions such as machine and component life cycles. Predictive maintenance allows you to service machinery before components fail. Further, if you know when something is going to break down irreparably, you can order a replacement that you can substitute when it’s required. As far as components go, you can also take advantage of 3D printing to create replacements more quickly.

3. Transparency

An intelligent supply chain management system makes the whole operation visible from end to end. Real-time data collected from connected devices provides you with more comprehensive insights into your business operations, on a scale you've never seen before. You can make faster and better-informed decisions, as well as contingency plans to cover unforeseen events like delayed shipments. In this way, you'll be able to minimise any negative impacts that might occur on the supply chain.

Investing in IIoT systems will give you greater transparency across your supply chain. This includes hardware like IIoT devices, RFID tags and remote sensors, as well as software solutions for ISC management. These include many advanced applications, including forecasting and planning, order management and AI/ML data analytics.

4. Pattern Identification

Collection and analysis of supply network intelligence across all your business operations will give you an overview of the whole ecosystem. With the actionable business intelligence supplied by AI and data analytics, ML is able to identify patterns, providing contextual intelligence to show up correctable anomalies. This applies not just to the supply chain, but to all your operational processes, logistics and distribution networks. Once you've identified definite patterns, you can formulate an action plan to deliver remedial action, which will demonstrate measurable success across the business ecosystem. You can then begin to identify new optimisations and efficiencies that will further cut costs, and so increase your revenue.

Implementing Intelligent Supply Chain Management

There are a few key steps to implementing ISC management, the first of which is automation. Automation is essential in increasing the overall speed of your operations, which is the first and most critical step in optimising your supply chain efficiency. Many other integral parts of your supply chain can also be made more efficient with automation. As well as optimising order fulfilment for all parties to your collaborative operation, you can streamline procurement, sourcing and distribution.

For example, you can attach IIoT monitoring devices to all your products, which allows them to be tracked right across the supply chain. This journey starts at ordering and purchasing, and goes through manufacturing processes and warehouse storage through to transportation vehicles and distribution routes. All along the way, it’ll be generating data from processes, products and vehicles, providing you with consumer insights. You’ll learn more about buying and selling cycles, inventory management, and stock control.

You should also think about automated hardware solutions for your manufacturing and warehousing premises, such as industrial robots and automated conveyor systems. Eventually, you might even be looking at automated delivery vehicles for the last mile of the supply chain to the consumer.

Implementing IIoT Solutions Successfully

To take the best advantage of intelligent supply chain management, you need to find the right balance between implementing IIoT solutions and using supply chain professionals. This technology will provide you with optimal efficiency, but only with the full commitment of all your personnel and partners. With a successful implementation, you’ll have full visibility of what’s happening now, and what’s likely to happen next, enabling you to keep your supply network fully on track.

Get More From Rowse Straight To Your Inbox