Festo Energy Saving Services

As a long-term authorised Festo Partner and Distributor, we at Rowse are keen to inform our customers about Festo's Energy Saving Services. As we all become more aware of the need to protect our environment and the climate, energy efficiency is an increasing concern. Optimising your energy efficiency also makes real business sense. Festo's Energy Saving Services can help users of compressed air equipment to identify and exploit potential cost savings.

Benefits For Rowse Customers

Festo's customised array of energy-saving services is systematic and sustainable, helping to reduce energy costs, while at the same time expanding production capacity. This offers enormous potential savings to compressed air users.

Greater Production Capacity:

- optimised machine status maintained

- production process more stable

- unplanned downtime prevented

- consistent production quality

Lower Energy Costs:

- compressed air generation more efficient

- compressed air consumption therefore reduced

- pressure drops avoided

The whole process involves a number of steps which can be separated into service modules if desired, and will provide a detailed picture of your system's energy efficiency.

- Initially, Festo experts look at the generation and preparation of your compressed air, in order to assess and analyse the system for possible weaknesses which can be optimised.

- Further assessments include an analysis of the compressed air quality, determining its consumption levels and measuring any pressure drops.

- A quick check is undertaken to demonstrate how leaks can affect performance, and a machine analysis carried out to establish energy efficiency.

Modular Design

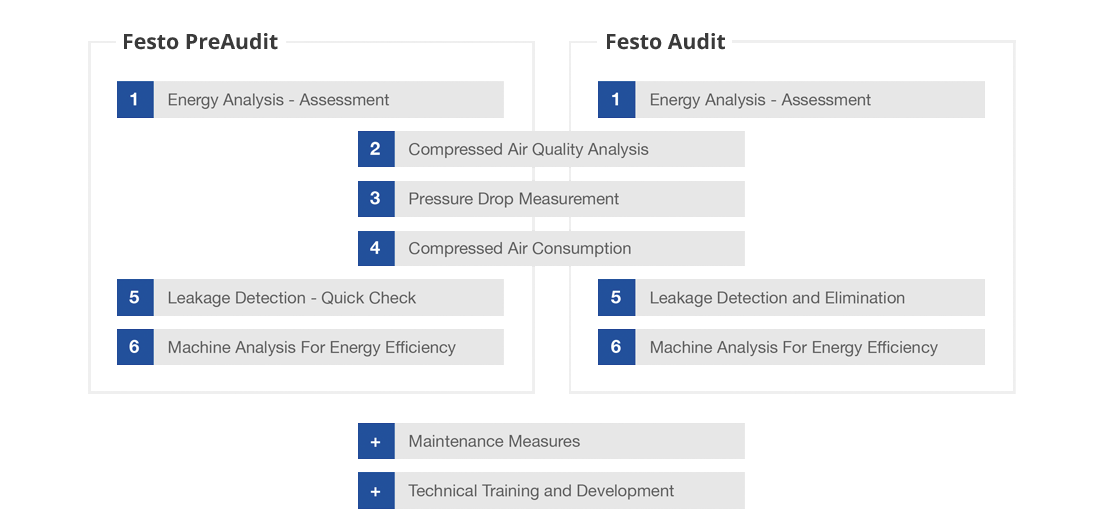

Festo's Energy Saving Services are designed as a selection of modules, so you can tailor them to your specific requirements. The three currently available options comprise a PreAudit service, a range of individual service modules, and a full Audit option. The faster PreAudit can show savings potential, while the full Audit offers customised energy efficiency options.

Festo PreAudit

The PreAudit module offers an analysis of your current system. A comprehensive report provides important energy-saving tips, and weighted recommendations on how you can optimise your plant's energy efficiency. The PreAudit module consists of the following steps:

- compressed air generation and preparation analysis

- compressed air consumption analysis

- pressure drop measurement

- compressed air quality analysis

- quick leakage detection check

- quick machine analysis check for energy efficiency

Festo Full Audit

The full Festo Audit is carried out along identical lines to the PreAudit, but with further comprehensive measurements additional to the initial energy analysis phase, and thorough elimination of any detected leaks. The full machine analysis is not just a quick check, but a thorough examination of your units to see how energy efficiency can be maximised.

Festo Unique Independent Service Modules

1. Compressed Air Generation Energy Analysis

This module is designed to provide a profile of compressed air generation and consumption throughout the entire system. Festo engineers monitor air generation for several days, including weekends and equipment downtimes. Compressed air and power requirements are also fully documented during equipment operation, including all consumption fluctuations. A report is then supplied to the customer, outlining the potential for energy savings based on this assessment.

2. Analysis of Compressed Air Quality

Festo engineers inspect service units and measure the quality of your compressed air, both centralised and decentralised. This detects the presence of any contaminants which might adversely affect system performance, and optimises compressed air quality. Customer benefits include an extended service life for pneumatic components, plus the possibility of adapting compressed air preparation to better suit individual requirements. Air pressure and temperature are also measured, and pressure dew point determined.

3. Measurement of Pressure Drops

These can be recorded by installing various pressure sensors around the compressed air system, complete with data loggers. Overall pressure can be stabilised to a constant which increases process reliability, and also reduced to a lower level, offering potential energy savings of up to 8%.

4. Analysis of Compressed Air Consumption

This service module offers precision analysis of your equipment to determine the exact compressed air consumption of each individual machine, both while operational and at rest. A Festo specialist team will look at various consumption parameters. These include volume flows and pressure levels. Precise determination of your system's status by individual unit will ensure you aren't using excess energy through oversupply, or suffering unexpected drops in pressure through undersupply. Each unit's configuration can be optimised, and any losses through leakage identified and eliminated.

5. Detection & Elimination of Leaks

Compressed air costs can be considerably reduced by systematic identification and elimination of leaks in the system. With this service module, Festo specialist engineers use ultrasound detectors to check your whole compressed air system, with no break necessary in production. They will assess and classify any individual leaks, from the compressor itself all the way through the system to the pneumatic application. A detailed list will then be prepared of all repair measures that may be required, including any replacement parts. Service data can be accessed online at any time by authorised customers using Festo's Energy Saving Assessment Portal.

6. Energy Efficiency Analysis

In this service module, Festo engineers conduct a systematic review of your compressed air applications, stabilising your existing processes and suggesting strategic system restructuring which can reduce your costs in the future. Based on this analysis, recommendations are made for optimising the energy efficiency of your pneumatic applications, including an estimate of possible costs, potential savings and predicted amortisation schedule. These suggested measures will be technically feasible, will make sound economic sense, and will be fully documented for customers. If you wish, you can then ask Festo to install and commission developed solutions based on their recommendations.

Maintenance & Training

Training courses are also offered by Festo to customers who have used their Energy Saving Services. These demonstrate innovative improvements, and help you identify the potential energy savings in your pneumatic applications. Recommended maintenance measures include regular analysis of all aspects of your compressed air system, and frequent inspections to identify and eliminate leaks.

Festo Energy Saving Services are certified under the International Standard ISO 11011, and by TÜV SÜD in accordance with that standard.