6 Ways AI Will Transform Warehouse Management

Post By: Ryan King On: 01-07-2019 - Industry 4.0 - Industry Trends

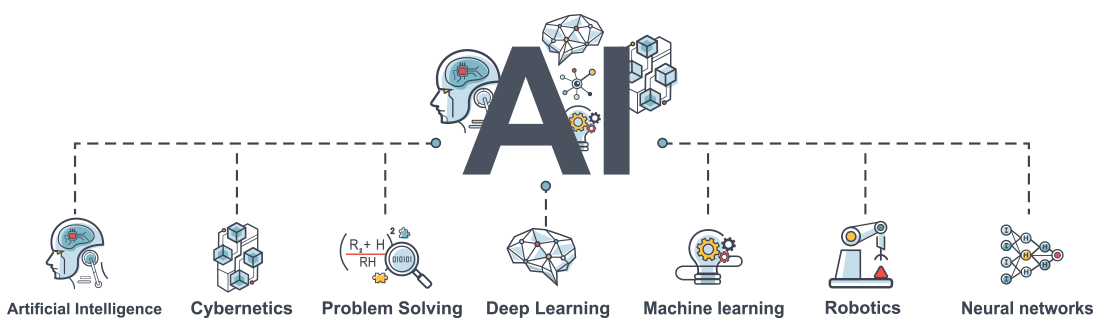

AI has left the cinema and reached out into real life, from our homes, transportation and mobile devices, to the groundbreaking developments in business and Industry 4.0. Artificial Intelligence and machine learning are rapidly revolutionising everything we thought we knew about industry, transforming warehouse management and supply chain logistics.

A smart warehouse combines various interconnected technologies to form an ecosystem whereby an entire business operation, from supply to delivery, is governed by AI. Goods are received at the warehouse, identified and sorted, processed, packaged, and pulled for shipment, all automatically and with minimal margin for error. Warehouse management will become more agile, with faster responses to logistical demands of material items and personnel, and more scalable in terms of finding new solutions for greater volume and flow of product.

Fully automated warehousing has not yet been achieved, but these are some of the ways AI will transform warehouse management:

1. Communication

Automated systems using AI and machine learning algorithms can communicate at an exponentially greater rate than human operatives. Many warehouse related activities are already automated, but introducing IIoT-enabled devices into these processes will vastly improve their speed and accuracy. Wireless I-O Link and Fieldbus data communications mean that all elements of the system can talk to each other, with a dialogue that incorporates system monitoring and control. Deep learning processes enable the machines to conduct constant analysis of the data streams produced by these components, enabling them to implement real-time adjustments and improvements in an integrated warehouse management system.

2. Warehouse logistics

Another way AI will transform warehouse management is by optimising the logistics, i.e. calculating the number of pallets or packages that need to be moved in any given day, and how much equipment is required to handle that movement. While this calculation previously relied on variables such as operator skill level and SKU (stock keeping units), machine-learning algorithms enable detailed stock movement forecasting and management to fine tune material handling. In this way, operator error and processing times can be reduced, with corresponding increases in overall efficiency and productivity.

3. Productivity

AI will further transform warehouse management by improving the productivity in pick-and-pack processes, with machine learning enabling managers to leverage the efficiency of the most productive pickers so as to develop a fully integrated system-directed solution. Slotting software products already provide an interface that includes operating rules to be implemented in the smart warehouse, offering a recommended SKU strategy based on sales histories and forecasts. While actual people still use personal knowledge and experience to adjust the slotting strategy, this will increasingly be phased out in favour of machine-learning algorithms.

4. Inventory

AI will also transform warehouse management by freeing up money previously spent on inventory control for other business growth opportunities. RFID (radio frequency identification) is replacing paper trails and bar code scanners for the organisation and control of inventory, tracking products with digital tags and enabling a more precise and accurate inventory control. Because the system uses radio waves to transfer data around, RFID scanners don't need direct line-of-sight control, but are just pointed in the general direction of a product to identify it and direct its movement into, around and out of the warehouse. This aspect of the smart warehouse can also be linked to the central AI processing unit, adjusting the speed and volume of order processing to increase overall productivity.

5. Robots

AI is already transforming warehouses with the use of robots, which can pick up goods and redistribute them within a fraction of the time required by human operatives. Machine-learning algorithms can help warehousing bots select the most efficient picking and slotting routes and determine the best type of packaging based on the size, number, weight and type of product. Some machines now can even pack the products themselves, using AI to optimise the space and materials.

6. Wages

Perhaps the most controversial way in which AI will transform warehouse management is in the reduction of payroll expenses, though this may initially be offset by the required technological investment. At the current stage of development, robot assistance impacts existing operations only as an aid to productivity, but AI could – and will – continue to improve machine handling capabilities, with 30% of UK warehousing jobs becoming fully automated by 2030. The likeliest sectors for automation are data collection and processing, and predictable physical activities. Large e-commerce enterprises suggest that increasing their automation will create jobs by expanding the overall scale of their business activities, but this remains to be seen.

Get More From Rowse Straight To Your Inbox