Pneumatics

Recent Posts

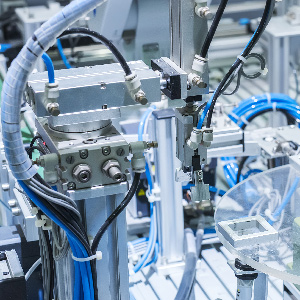

How Pneumatic and Automation Systems Work Together

Post By: Tom Rowse On: 06-10-2023

Five years ago – a long time in technological terms – “The Evolution of Advanced Automation” was discussed in a presentation at the Industry & Economic Outlook Conference in the United...

11 Steps: Troubleshooting Pneumatic Systems

Post By: Tom Rowse On: 26-10-2020

Pneumatic systems comprise a number of complex and interlinked components, which need comprehensive and careful tuning to run at their optimal performance. Needless to say, optimal performance is not always the norm...

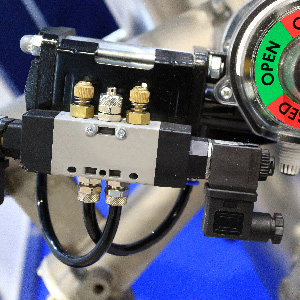

What Are NAMUR Valves?

Post By: Tom Rowse On: 15-10-2020

Depending on the circles you move in, it's not unusual to hear the question, “What are NAMUR valves?” NAMUR is one of those strange acronyms that appear to bear no relationship whatever to their meaning...

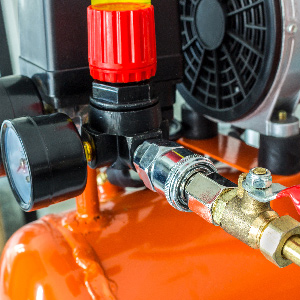

How To Troubleshoot An Air Compressor

Post By: Tom Rowse On: 15-09-2020

The problems you're most likely to encounter with an air compressor fall into four general categories...

How To Choose The Right Process Control Valves

Post By: Tom Rowse On: 03-08-2020

Control valves are critical to the establishment of an efficient process and smooth running over the lifetime of a system...

Get More Pneumatics Content From Rowse Straight To Your Inbox

Welcome to Pneumatics at Rowse, where we keep you up to date with everything that's going on in the world of compressed air power. As much as 90 percent of manufacturing facilities around the world use some form of pneumatic machine process, and as factories become increasingly automated, pneumatic design and engineering becomes ever more sophisticated. At Rowse, we have amassed a strong pneumatics knowledge base, founded on 15 years in the business, and the wealth of combined experience of our design and engineering teams.

What is Pneumatics?

Pneumatics is possibly the oldest field of engineering physics, dating back to prehistoric times. It works by manipulating the energy obtained by compressing air or gases in order to perform mechanical tasks. Human beings originally discovered this when they used air expelled forcibly from their lungs to blow on sparks and light a fire, or to hunt with darts blown out through a hollow stalk. The word comes from ancient Greek: pneuma means "a blowing", a noun form of the verb "to blow". Pneu in French and Portuguese means tyre (because you blow it up), and the word is also used medically in association with the lungs (e.g. pneumonia).

A typical pneumatic system today employs a motor-driven compressor to (roughly) halve the volume of ordinary atmospheric air, and in the process to double its pressure. This pressurised air then passes through a series of pneumatic hoses to a cylinder, where it accumulates as potential energy. The potential energy of the compressed air is used to produce kinetic energy, which controls some type of mechanism and operates with either linear or rotary motion.

Pneumatic technology today has spread into a great number of previously impossible applications. These include medical applications, semiconductors and robotics, precision materials handling/packaging and entertainment (especially animatronics). Pneumatics are also very useful in hazardous or extreme environments where electrical power is too great a risk, such as explosives.

How Can Rowse Help with Pneumatics?

We're always keeping abreast of technological and market innovations in pneumatics, as well as being a technical distributor of advanced pneumatic systems and components. We are also the authorised distributors and premier stockists for many of the world's leading pneumatics manufacturers, including Festo and Camozzi. Rowse is an authorised Festo Partner and carries Festo's full product portfolio.

As acknowledged pneumatics experts, we have had the privilege of helping many local and national manufacturers to refurbish or upgrade their pneumatic systems. We are experts in locating current and obsolete parts, and can help source the right parts for all sorts of pneumatic applications, so that even an ageing system can be refurbished and its productive working life extended.

Our team at Rowse is always delighted to arrange a site visit, where a risk assessment exercise will be conducted by our experts in design, automation and machine safety. Our pneumatics team works in full consultation with you, to ensure that all pneumatic equipment is delivering optimum performance, and that the system and its components are installed in full compliance with the most up-to-date safety regulations.