How Pneumatic and Automation Systems Work Together

Post By: Tom Rowse On: 06-10-2023 - Automation & Control - Industry Trends - Manufacturing - Pneumatics

Five years ago – a long time in technological terms – “The Evolution of Advanced Automation” was discussed in a presentation at the Industry & Economic Outlook Conference in the United States, held by the National Fire Protection Association. The premise at that time was that design engineers might be moving away from pneumatics, but that pneumatics could continue to grow as an industry if approached in the right manner.

The recommendation was for a seamless integration of pneumatics and automation, that would rely heavily on IIoT adoption and more compact, efficient machines. The presenter, Donna Ritson of DDR Communications, outlined how pneumatics might continue to advance using smart technologies and data collection. Pneumatic applications would require effective data gathering and manipulation, remote servicing, preventive maintenance, more efficient machines – and much more – in order to increase their level of intelligence.

The goal was to achieve a greater level of automation so that pneumatic and automation systems work together. This would require intuitive and interactive HMIs: as factories become more automated, they have less skilled labour. What operators there were would want simpler machines that were more intuitive. The idea was that the machinery itself should provide the initiative for preventive maintenance, by setting off alerts and alarms for the operator. Smarter sensors would be installed to tell workers when a component is wearing out and what adjustments or responses needed to be made.

Pneumatic And Automation Systems Working In Harmony

Since the 2018 conference, the automation industry has made great advances in digital transformation. The idea of pneumatics becoming outdated has itself become obsolete thanks to the integration of evolving pneumatic technologies. These include control valves that incorporate sensors, wireless technology and industrial network interfaces.

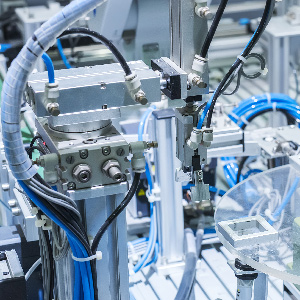

Complex digital control features offer access to smarter, actionable information that significantly improves the efficiency of automation applications. Plug-in valves and manifolds were also created, which meant that all the solenoid valve connections which were previously linked separately to the PLC could be achieved using a single cable. Integrating IIoT technology means that pneumatic valve systems now incorporate much more advanced electronic features, providing pneumatic-driven actuators and applications with a whole new level of precision control.

Valve system control modules for pneumatic positioning applications are able to incorporate proportional-integral-derivative (PID) controllers, which can automatically monitor and adjust control functions. Such high-tech pneumatic capabilities allow greater precision in end-point motion accuracy. Used in conjunction with a PLC, they also have the capacity to switch in real time from position control to force control. Motion sequences for very advanced automation tasks can be accurately fine-tuned, increasing reliability, repeatability and product throughput.

Automation systems continue to evolve into a more sophisticated, connected partnership with pneumatic applications. Industrial network communications were established via fieldbus connectivity, increasing the control capabilities of a PLC. As well as controlling valves, the newer PLCs can also monitor sensors and other connected devices. Instead of several local I/O cards, they are able to exchange I/O data via a single communication cable.

Evolution Of Smart Pneumatics

As the automation platforms became smarter and more sophisticated, so did pneumatics. Design engineers began to incorporate both I/O capability and fieldbus interfaces into pneumatic valve manifolds. These provided complete pneumatic valve packages, far more versatile than previous discrete components and engineered to be easily integrated into advanced automated systems.

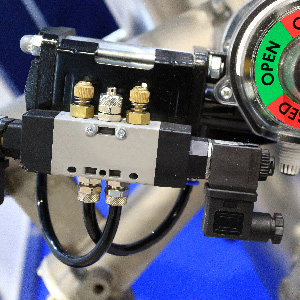

A further step forward in valve technology came with the integration of electro-pneumatic control capabilities into the valve manifold. This greatly enhanced their versatility and performance capabilities. New technologies also allowed more accurate control of proportional regulators using digital signals. Fieldbus connectivity integrated into these devices was also able to optimise the force and pressure requirements in any given production system.

Why It’s Important

In the 2018 survey, manufacturers wanted pneumatic components that were more robust, durable and energy-efficient, as well as easily and reliably available. They asked for smoother and more user-friendly pneumatic systems that would increase motion and speeds and offer better precision. And with all that, they wanted pneumatic components that were easier to maintain, more compact and, most of all, repetitive.

Ritson noted in her presentation that all these pneumatic technologies had already been developed in 2018. For example, cylinder-mounted and linear slide sensors were already designed with continuous position sensing and supported rapid maintenance and replacement. But what was more interesting from the point of view of the survey, was the gap between the perception of the end users and reality.

Although the technological capabilities already existed, one of the biggest challenges for suppliers was to educate the industry about its existence. Many end users were not aware that the technology was available and consequently had failed to invest in these advanced solutions. Ritson concluded that more companies needed to connect the capabilities of pneumatics and automation systems working together and install smarter machines in their facilities.

This Is The Future Of Manufacturing

One of the primary objectives of digital transformation in manufacturing in particular, and the IIoT in general, is the collection of actionable information. In manufacturing, it provides more sophisticated and optimised control, step by step throughout the production process. For example, pneumatic valve systems with built-in intelligence offer new opportunities for such precision monitoring and control.

A well-designed predictive maintenance system integrated into a valve can capture and use minutely accurate information that will optimise and prolong the working life of pneumatic applications. If the system determines that a component is in imminent danger of failure, it may even implement an automated requisition for a replacement before that actually happens.

More Productive, Cleaner And Energy-Efficient

As pneumatic components become smarter, they’re able to generate many more data points to improve the production systems in which they’re used. These data points include usage statistics, diagnostics and lifetime data, which can be used to maximise uptime in production systems, control their energy consumption and make systems run more efficiently.

The advanced level of control achieved by combining pressure and directional controls greatly increases the versatility of pneumatics. It also enhances its value for a much greater range of automation applications. Smart pneumatics provides more precise, efficient and optimised control for automated applications in the manufacturing process.

When pneumatics and automation work together, factories become more productive, cleaner and energy-efficient.

Get More From Rowse Straight To Your Inbox