How 3D Printing Lowers The Cost Of Product Development

Post By: Ryan King On: 01-08-2023 - Industry 4.0 - Manufacturing

In traditional manufacturing, the design, development and production processes were usually slow. You had to take great care to get the design just right before any manufacturing could take place. This was inevitably expensive and sometimes stressful. It meant some manufacturers could only roll out a couple of new products a year, limiting the potential for expanding product lines.

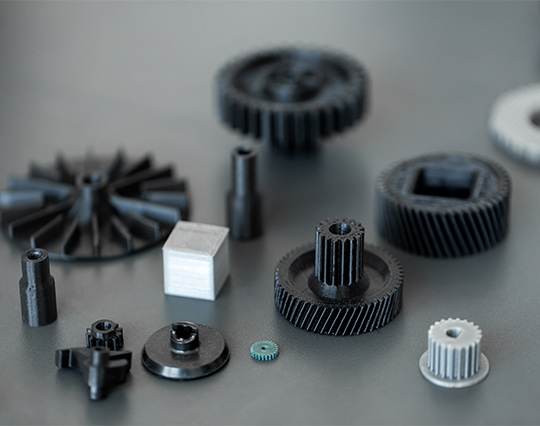

This situation is changing radically with the advent of Industry 4.0 and increased integration of 3D printing technology, or additive manufacturing. It means even smaller companies can greatly speed up their product development process.

The rapid evolution of 3D printing technology has made it faster, more automated and capable of greater production volumes. Developments have reached a point where the technology offers manufacturers significant production value. It means manufacturing costs can be significantly reduced in all aspects of manufacturing, all the way from R&D to actual production.

Here are some ways in which 3D printing lowers the cost of product development:

- Faster and cheaper design process

- Lower labour costs

- Lower material costs

- Design agility and customisation

- New design horizons

Faster and Cheaper Design Process

Perhaps the greatest advantage of 3D printing technology is the cost saved in prototyping. Rapid prototyping is still one of the main uses for additive manufacturing. Prototypes that used to cost hundreds can now be made for a fraction of that cost, so even small-scale businesses can actively pursue product development.

In the past, product design engineers would start with very basic mock-ups, which a professional developer would use to produce a more refined functional prototype. 3D printing is based on digital technologies, so all this is now done by computer modelling. You only have to alter the CAD data to make a fresh iteration of a prototype. This means you can make multiple iterations much more cheaply and rapidly than by conventional manufacturing techniques. This leads to an accelerated product development phase, as corrections and improvements to a design can be made early on.

Lower Labour Costs

Another way 3D printing lowers the costs of product development is by reducing the amount of labour required. Before now, models, tooling and prototype parts all had to be made manually or by operating a machine. This could be very expensive and labour-intensive, especially in applications using metals. However, some companies are now offering cost-effective 3D printed prototype solutions, even for metal. Prototypes can be printed from CAD files as soon as they’re complete. As a result, the production time for prototypes is reduced from weeks to hours and labour costs are much less.

Lower Material Costs

3D printing also lowers the costs of product development by reducing the amount of raw materials required. 3D printing is the common term for additive manufacturing, which means adding raw materials layer by layer. The printer only uses what’s required to print, dramatically reducing material waste. Traditional manufacturing methods are subtractive, cutting or whittling away excess material, and typically producing more waste. This makes 3D printing more resource-efficient, especially when using high-value materials.

The technique also allows you to use less material to produce any given part. A good example of this is metal lightweighting, which uses 3D printing technologies to make metal parts lighter. In some industries like motorsports or aerospace, weight to speed ratio is critical, so that even one ounce saved could represent significant economies.

Reducing weight with subtractive manufacturing requires the more expensive removal of material from a part. Cutting, drilling and machining add to the work required and thus mean extra cost. With 3D printing , this process is reversed: the lighter the part, the more cost-effective and rapid the production process.

Design Agility and Customisation

The versatility of 3D printing also makes it more cost-effective. Now that design engineers work digitally, the designs can be infinitely variable. This means that customised designs are less pricey. We’ve seen that you can use your 3D printer in the development stage to create multiple iterations of a prototype, cheaper and faster.

You can also modify any existing product’s digital file, with very little time or expense. Manufacturers like Nike and Gillette are now able to offer personalised products to customers, with minimal additional cost to the main production line items.

Furthermore, a 3D printer is able to produce a wide variety of different items. A single machine using digital models can create practically any product. You no longer need customised moulds for unusual or special order objects. Traditionally such products – like, for example, surgical instruments, prosthetic limbs or human tissue – would incur high individual costs. With additive manufacturing, such items will cost roughly the same to produce as any other item using the same amount of raw material.

New Design Horizons

3D printing allows affordable customisation and offers new horizons for product designers and engineers. With no restrictions on tooling and material stress parameters, they can experiment with more complex designs. Additive manufacturing permits geometries that aren’t feasible with any other manufacturing method. Forward-thinking companies can continue to maintain product innovation while still achieving cost savings in development.

One way this has been demonstrated is with part consolidation, where developing products for additive manufacturing has proved really cost-effective. Instead of producing and assembling multiple components to create a final part, 3D printing can print the whole thing as a single, integrated part. This allows manufacturers to make significant cost savings, such as the labour costs of assembly. Maintenance costs are also lower, as the product performance is better and inventory costs are lower as you need fewer individual components.

3D printing lowers the cost and saves time in the overall development process. Other aspects of production using additive manufacturing allow businesses a host of additional benefits. These include low volume and on-demand production, especially of obsolete parts. The agility of design and versatility of production make 3D printing useful to practically any business where physical product development is required.

Get More From Rowse Straight To Your Inbox