Introduction to Industry 4.0

Post By: Ryan King On: 16-08-2018 - Industry 4.0 - Industry Trends - Manufacturing

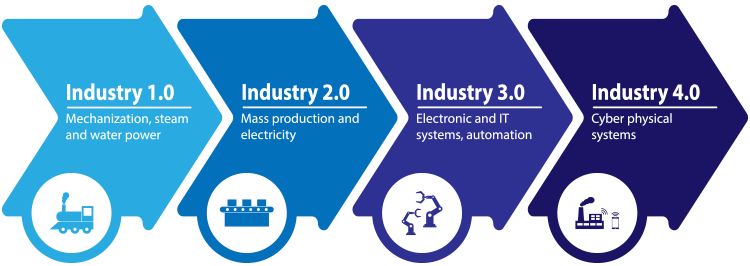

If you haven't heard the term before, Industry 4.0 is the short form for the major shift in human activity called the Fourth Industrial Revolution, where we turn from basic mechanical and digital power to integrated biological and cyber power. In this new era of human advancement, things are becoming more comprehensive and more fluid, with quantum computing, 3D printing and biotechnology driving systems that can govern much more than simple production machinery.

Industry 4.0 demonstrates a technological evolution to advanced cyber-physical systems, with an industrial Internet of Things using largely decentralised machine intelligence. It's a very broad vision of the future that sees all things connected, and one which can affect much more than industry. From control systems in manufacturing, production, and supply chain logistics, automation is spreading across all sectors of life from smart cities to energy management, healthcare and transportation. The possibilities are infinite at this early stage, but the first step is to explore the potential of Industry 4.0, and how it will impact the world as we know it.

There are major areas of concern, not least the generalised fear of AI taking over from human control, but also involving the financial investment required to change all our existing methodology and equipment to the new systems. Then there is the changing nature of business itself, with end-to-end digital supply chains governing every move - from planting a row of peas, to buying a packet of frozen ones at the shop with automated check-out, or online ordering and delivery. Consumers are having more control over how and where products are sourced, and delivery commitments can be more effectively enforced, with every aspect of the supply chain monitored by smart contracts and blockchain technology.

Manufacturing and production is increasingly governed by a network of powerful computers and data management tools, with human-machine interfaces (HMI) enabling complex and remote control of bigger and better systems. Information exchange takes place via cloud-based technology, which breaks down the traditional pyramid of business practice into a model which has more vertical as well as horizontal interaction. Automated systems can be as simple as a conveyor belt, or as complex as Britain's air traffic control network, and it all relies on programmable logic controllers (PLCs) and high speed wireless communication between devices.

With Artificial Neural Networks, machines can learn in the same way as we do, speeding up response time and constantly updating information. Industry 4.0 will see more manufacturing processes being automated and existing ones improved, with smart technology governing ever-increasing applications in our daily lives. This evolution in the way we do things has seen the birth of an independent Rowse Automation, where we are investing our years of experience and technical expertise to help drive the world forward.

Get More From Rowse Straight To Your Inbox