4 Technologies Pushing

Industry 4.0 Forwards

Post By: Ryan King On: 28-08-2018 - Industry 4.0 - Industry Trends

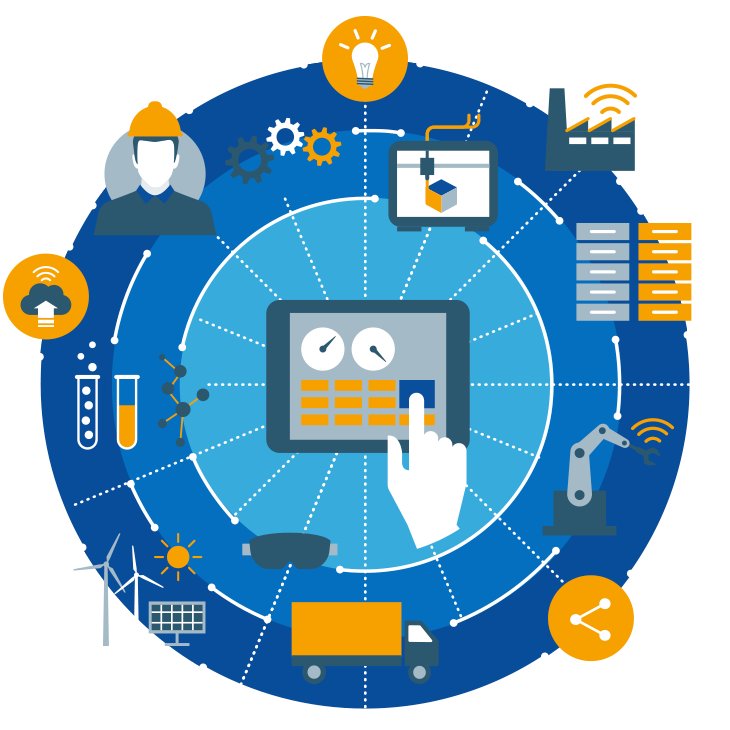

Industry 4.0, the fourth industrial revolution is here. In recent years we have witnessed numerous developments which are pushing technology forwards. This development in technology has lead to what is now known as Industry 4.0. More and more businesses are starting to adopt these new technologies and incorporate them into their processes.

We are currently seeing four critical areas of development that are pushing Industry 4.0 forwards, and we are exploring these four areas and seeing what impact they are having in industrial settings.

1. Data

Data has always been an essential tool for businesses when making decisions. However, data analysis has only been improving in recent years with the development of artificial intelligence (AI) and data analysis tools. The term, Big Data, has been used to describe this age of large amounts of information that are being collected and analysed by systems. This movement has led to companies making use of their historical data and improving the collection of data with the aim of using this data to speed up processes, improve quality and reduce costs.

With the advancements in data analysis developers are working on solutions to discover problems quicker and put measures in place to reduce risk. These systems also allow businesses to predict life spans and potential issues before it is too late.

2. Connectivity & Communication

The last ten years have seen one of the biggest developments in technology which has benefited the domestic and industrial sectors. The growth of the internet in the last ten years has seen more locations around the world get connected and the speed increase significantly. Approximately 3.58 billion users have access to the internet, according to statistics website, Statista.

Developments in global connectivity have allowed businesses to distribute manufacturing and share resources and data at speed resulting in lower costs and greater access to distribution networks. Technologies like remote database access (RDA) and radio frequency identification (RFID) allow businesses to collect more data than ever, track processes and aid in the distribution of data between locations and companies.

3. Hardware

It's hard to miss the fact that computing power has increased significantly in the last few decades. This increase in computing power has allowed the quicker processing of data & the development of artificial intelligence decreasing time spent on data analysis.

Manufacturers have incorporated more technologically advanced systems into factory machinery with integrations with a multitude of systems and software. This development has enabled businesses to gather data from the factory floor and store the information at scale for analysis by data tools. Combined with greater connectivity and communications, enterprises have achieved more sophisticated automation, monitoring and responses to issues that arise in industries like automotive and manufacturing.

4. Software

Businesses have been working closely with developers to build new tools for monitoring, reporting, automation and communication. This software development has been taking all the improvements in hardware, communications, connectivity, data and combining them to create highly sophisticated systems that allow businesses to run leaner and increase outputs while reducing costs.

As we have seen, there are many technologies which are pushing Industry 4.0 forwards from all areas. While many businesses are pushing forwards with developments to improve, there are still companies that cannot allocate the budget or time to these developments, but the investment by larger businesses is making technology more accessible to smaller firms.

4 Technologies Pushing Industry 4.0 Forwards

If you enjoyed this content you can download the PDF version to share.

Get More From Rowse Straight To Your Inbox