What Is Lean Manufacturing?

Post By: Ryan King On: 16-12-2022 - Industry Trends - Manufacturing

Lean manufacturing is the name of a production methodology. Its benefits lie in reducing operating costs and lead times, and improving product quality. Its principal focus in manufacturing systems is simultaneously to maximise productivity and minimise waste. Waste is perceived as anything that customers aren’t willing to pay for because they don’t believe it adds value.

Lean manufacturing is a practical methodology that can bring advantages to organisations from many sectors. It’s employed by several well-known companies, starting with Toyota and followed by Nike, John Deere, Intel and many others. The ideology was formulated for use on the Toyota Production System in the 1970s, and they still use it today. It can also be combined as a methodology with enterprise resource planning (ERP) or Just-in-Time manufacturing (JIT).

What Is The Origin of Lean Manufacturing?

Lean manufacturing came about as a result of Japan’s post-World War II thinking on production and quality. Manufacturers decided to apply some philosophical principles to practical matters, such as Kaizen. This is a Japanese compound word made up of kai (change) and zen (good). Translated together, the new word stands for ‘good change’ or improvement. As it developed in use with lean production methodology, Kaizen generally means ‘continuous improvement’.

Toyota applied the principles of lean manufacturing for some 20 years before the idea became generally known. This happened when MIT researchers published a book about the future of cars in 1990, using Toyota's lean production system as a case study. Since then, the book has become the foundation of lean manufacturing concepts. Its principles have had a profound influence on industries worldwide, and not just on manufacturing. Other sectors embracing lean manufacturing include software development, logistics, service industries and healthcare.

Lean Manufacturing: The Five Principles

Another book was published six years later, in 1996, which laid down what many consider to be the method’s core ideology. Lean Thinking: Banish Waste and Create Wealth in Your Corporation itemised five key principles of lean, which now form the foundations of lean implementation. One of the book’s authors went on to found the Enterprise Institute (LEI) in 1997, using these five core principles.

1. Value

The producer creates the value, but it must first be identified and defined from the customer's perspective. Companies producing goods or services need to understand what value the customer places on them. This then helps companies decide how much money they think the customer will pay.

To achieve the ideal balance between maximum profits and optimal value, the company must focus on eliminating waste from its business processes – and thus reducing costs.

2. Value Stream

The value stream of a product must be mapped through its entire lifecycle. All the materials and information which are necessary to create a specific product or service must be recorded and analysed. The purpose of mapping this flow is to discover and eliminate all areas of waste and identify any potential methods of improvement.

3. Flow

Flow is the key factor in waste elimination. It means getting rid of functional barriers and finding ways to improve lead time. This will ensure a smooth flow of production processes, from receiving an order to delivery. Without interruptions or bottlenecks in these processes, they become fully integrated into a harmonised flow of activities.

4. Pull

Lean manufacturing works on a pull system (kanban), which relies on communication and flexibility. This means that nothing is bought or made unless there is a demand for it. A system of signals is used to show when more materials are required, which are then automatically replenished. This eliminates waste from overproduction and inventory. It regulates the flow of goods throughout the whole production process, from material supply to product delivery.

5. Perfection

Lean manufacturing is founded on the continual struggle for perfection, the good change of Kaizen. This entails all members of the organisation working cooperatively together, to seek out and eliminate waste throughout the value stream. It requires a relentless pursuit of waste, to get to perfection through continuous improvement.

Identifying The Waste

Toyota identified seven main areas where waste was preventable. These included time, and use of resources that don't provide the customer with any value.

Primary areas of waste are defective products, excess inventory, and using more processing steps than are strictly necessary. Time is also wasted when people or machines are lying idle, or moving when they don’t need to. All Toyota’s elements of identifiable waste mesh with each other, producing even more waste. The combination eventually ends up wasting the time and efforts of the company’s management.

Some Lean Manufacturing Concepts

Some of the most important Japanese concepts are used by many as a toolbox for improving manufacturing operations.

Jidoka (Automation With A Human Touch)

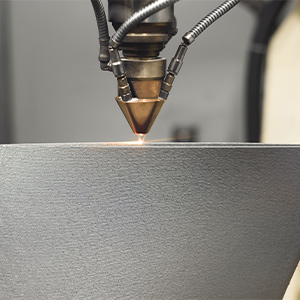

One of Toyota’s first steps in improving production was partial automation. They gradually introduced automated manufacturing processes by hand until they were proven safe. In this way, they saved on the costs of full automation, but also of labour as the number of human workers was reduced. It was designed to ensure that machinery would detect defects instantly and stop automatically. This meant improved quality and less waste in defective products.

Andon (light)

Toyota introduced a visual feedback system, incorporating tags, signals and lighting indicators on the factory floor. These show production status at a glance and provide instant alerts if assistance is required. Visual feedback also empowers human operators to halt the production process immediately if any problem arises.

Heijunka (Level Scheduling)

This approach streamlines production scheduling. Companies intentionally manufacture products in much smaller batches, thus reducing inventory. Product variants that can be made within the same process are mixed together, or sequenced. When each item is manufactured more frequently, lead times are reduced.

Acceptance And Advances

In the half-century since the lean manufacturing concept was initiated by Toyota, the core principles have been widely accepted. Many companies have adopted lean production techniques, and others have developed their own take on the key ideas. Institutes and research centres have brought lean into business management, and new technologies are enabling great advances in waste reduction.

Get More From Rowse Straight To Your Inbox