What Is Lockout Tagout?

Post By: Tom Rowse On: 17-08-2022 - Industry Trends - Manufacturing - Safety

Lockout/Tagout (LOTO) is a mandated set of safety procedures operational in the United States, under the governance of the US Department of Labor's Occupational Safety & Health Administration (OSHA). These measures are put in place to ensure that any equipment, energy sources or dangerous machinery undergoing repairs or maintenance is fully shut off while such work is being carried out.

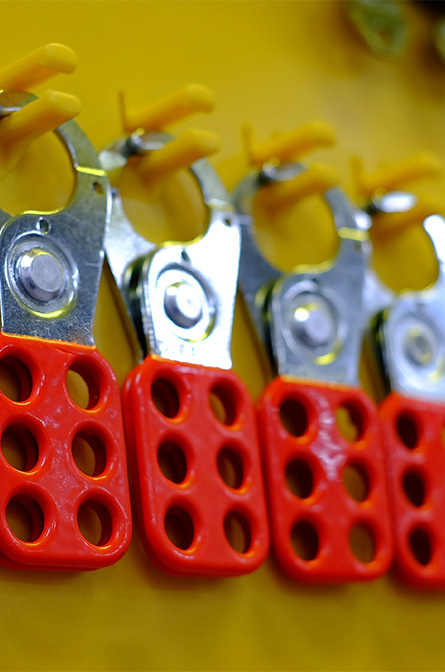

All equipment or systems must be securely shut down and rendered inoperable so that they cannot be activated before these works are complete. LOTO devices include electrical, cable and valve lockouts, padlocks, hasps and safety tags, as well as lockout stations, group lockout cabinets, and lockout kits.

Does It Apply To Us?

Technically there is no equivalent legislation in place in the UK, though the IEE Wiring Regs that comprise BS7671:2018 do lay down general safety requirements governing electrical installations. In addition, the Provision of Work Equipment Regulations (PUWER) 1998, which govern the safety of manufacturing equipment, refer generally to safeguards and protective measures. Some of its provisions reflect the procedures advocated by OSHA, such as isolating all equipment from power sources. These procedures also form the basis of the European Directive governing the safety of work equipment, which indicates that LOTO devices should be used.

What Does It Mean In Practice?

LOTO procedures and safety devices protect workers against the accidental release of hazardous energy in any workplace scenario where workers might be harmed. This term is not limited solely to electricity but includes other forms of potentially hazardous energy, such as pneumatic, hydraulic, mechanical, gravitational, thermal, chemical and radiation.

The procedures are designed to prevent workers from being directly exposed to such energy sources by using LOTO security devices. They also protect against any injury indirectly caused by the movement of other objects or machinery, as a result of that energy being released. Sudden loss or exhausting of pneumatic or hydraulic pressure, for example, can cause mechanical parts to move unexpectedly. The kind of accidents which following LOTO procedures can prevent include lacerations, crushing, electrocution, chemical exposure, burns and amputations.

How Does It Work?

The main purpose of these procedures is to install a locking device that directly blocks access to the power source, to prevent anyone from switching the equipment back on. A tag is then attached to the lock that alerts others to the hazard status of the locked device and warns them not to attempt to start it up. Once the system has been de-energised and locked out, a test should be carried out to make doubly sure that it’s not possible to re-energise it without removing the lock.

LOTO procedures aren’t obligatory in the UK, but they make good sense and it’s advisable to follow them. If you do go down this road, LOTO must be instigated from the ground up, so that all employees are trained to understand the principle and to follow precisely the same programme. You could start by carrying out a PUWER assessment, which identifies the sources of hazardous energy that are most likely to need attention.

Setting Up A LOTO Protocol

There’s more to this than just investing in some locking devices and tags. To set up a good lockout protocol you need to conduct a thorough risk assessment, and make sure to incorporate these basic LOTO procedures:

- Develop a single, standardised set of rules that all employees must follow

- Initiate training on following the procedures

- Invest in lockout devices to prevent access to any equipment or power source that may inadvertently be activated during maintenance work

- Make sure that all new or modified equipment is capable of being locked out

- Devise a system of tagout procedures to indicate a locked-out hazard, to be used in tandem with lockouts unless they’re strict enough to provide the same degree of protection as a lockout device itself

- Institute a tracking procedure that logs every instance of applying or removing a lock or tag, including a record of who placed and/or removed them

- Institute a fixed system of information to be recorded on a tag, including why the lockout has been applied, by whom and when

- Draw up guidelines indicating who is permitted to attach and remove locks and tags, emphasising whether this should or shouldn’t always be the same person

- Set up a tracking procedure that records every instance of LOTO being applied, either by a paper record or with dedicated tracking software

- Initiate an annual routine inspection of LOTO procedures to ensure their performance is of an acceptably high level

What Are The Pros And Cons Of Using A LOTO System?

Setting up and applying a LOTO system helps to keep your workplace safe and in compliance with relevant legislation. It reduces the risk of worker injuries caused by equipment and machinery while it’s being serviced and maintained. The risk of encountering hazardous energy is eliminated, together with the risk of damage occurring to that equipment or machinery if it’s turned back on before repairs or servicing are completed.

One commonly encountered problem is knowing how to distinguish between maintenance and minor routine operations. Is it necessary, for example, to follow LOTO procedures when changing a drill bit or light bulb, altering the speed of a drive belt or correcting the position of an item on a conveyor line?

Employees don't always understand and recognise the necessity for using LOTO in any given situation, and sometimes just do it by guesswork. Without a clear LOTO protocol, people can be confused about who's responsible for carrying it out.

Uncertainty may also arise about which kind of locks or tags to use and where to use them, so both locks and tags must be clearly identified as indicating a hazard. As with emergency stops, this is often accomplished by making them red, with large lettering.

Applying LOTO to a specific item doesn’t always control all the sources of hazardous energy. It’s possible to overlook associated sources, such as a neighbouring conveyor or overhead crane, kinetic energy and/or gravity. A machine may have separate individual circuits running to it, which must all be identified.

Get More From Rowse Straight To Your Inbox