3D Printing Issues Manufacturers Face

Post By: Ryan King On: 26-07-2023 - Industry 4.0 - Manufacturing

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.

While prototyping continues to be an important feature of 3D printing, the focus is now inclined more towards end-use production. It’s used in many industry sectors to introduce new and innovative manufacturing solutions that perform better and are more efficient. Industries such as automotive, aerospace, energy and medical are using 3D printing for producing parts – and it’s also transforming conventional manufacturing processes like injection moulding.

These are some of the leading trends in 3D printing – and the issues manufacturers face when incorporating it into their production processes:

- Bringing 3D Printing In-House

- Bigger Focus On Designing/Printing Spare Parts

- Using 3D Printing With Other Manufacturing Techniques (Hybrid Manufacturing)

- Speed and Accuracy

- Build Size Limitations

- Environmental Impact

- Knowledge and Skills Gap

Bringing 3D Printing In-House

Rapid prototyping is still a leading function of 3D printing technologies, simply because it’s so quick and cost-efficient to do. High-quality prototypes can be produced that can be used both for visual analysis and functional purposes like testing and evaluation. If a 3D printer is installed in-house, it enables product designers and engineers to design, produce and interact with 3D models, to assess their viability and integrate necessary changes. As soon as they do this, new iterations can be printed right away.

This agility is very beneficial in reducing production lead times. The rapid production of modified designs ensures that engineers end up with the best possible part design. Installing in-house 3D printing technologies also eliminates component shipping times and time spent waiting for third-party manufacturers.

3D Printing Spare Parts On Demand

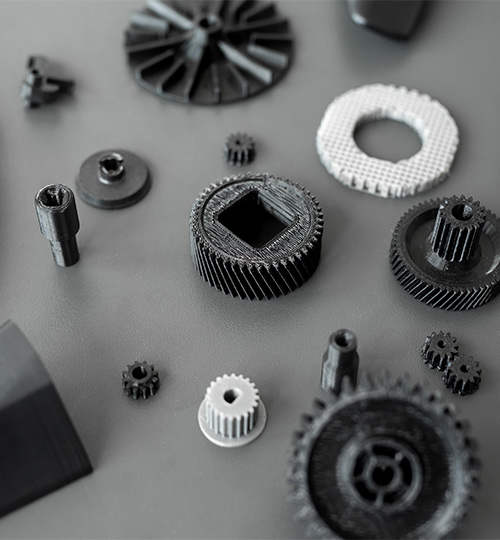

3D printing is already revolutionising spare parts production, as manufacturers don’t have to face the challenges of traditional procedures. These include long lead times, the costs of inventory and warehousing, plus complex logistics as components are transferred from place to place. 3D printing allows manufacturers to create digital inventories and use them to produce replacement parts on demand. Several industry sectors are already creating parts this way, and it’s also proving very valuable for recreating obsolete parts. Items that are rare or no longer available can be scanned from existing versions and reproduced, with no need for expensive tooling.

This is particularly useful for things like military or railway components. Previously, a supplier would have had to invest in custom moulds in order to reproduce components, which took both time and money. Now small parts like bolts, brackets, hooks, etc, can rapidly be replaced, minimising downtime for maintenance.

The versatility of 3D printing means that a wide variety of materials can be used, including metals, thermoplastic composites, industrial-grade plastics and ceramics. So many new high-performance applications can now be explored.

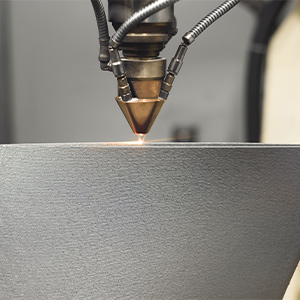

Using 3D Printing With Other Techniques (Hybrid Manufacturing)

As 3D printing technologies advance, they’re also able to enhance the efficiency of traditional manufacturing processes. Integrating additive manufacturing into things like injection moulding and machining creates a hybrid approach. Near-net shapes can be 3D printed, which can then be finished with CNC machining to achieve tight tolerances.

Another example of hybrid manufacturing prints a 3D mould in a soluble material. The mould is used for injection moulding of components and then dissolved, leaving behind a finished prototype.

Overcoming 3D Printing Speed Limits

Another of the 3D printing issues manufacturers face is speed. Although it’s usually faster than traditional methods for one-off or small-batch production runs, it’s generally too slow for larger volumes. But system developers are improving build times – both printhead or laser speed and print bed stacking and orientation. Many time-consuming post-production steps are also being automated, which increases efficiency.

Limitations In Build Size

The size of a 3D printer dictates how large an item it can print – and most systems can’t normally print large parts. 3D printing has therefore mostly been used to produce parts that are less than 5.38 feet square. This naturally limits the type of applications it can be used for. In some cases, manufacturers have had to print 3D models like a jigsaw puzzle and then assemble the multiple segments. This can influence structural strength and increases post-production time.

Happily, this size limitation is now being overcome and large-format 3D printing systems are now available. Wire arc additive manufacturing has enabled large-scale 3D printing of metals – a famous example being Amsterdam’s printed stainless steel bridge. Fibre-reinforced extrusion technologies have also enabled the production of printed items over 10 feet square.

Environmental Impact

3D printing is perceived as a greener production technology. It produces on-site and on-demand, creating lighter, more fuel-efficient parts. However, there remain the issues of materials and waste. The most commonly-used 3D printing materials are still plastics, mostly derived from fossil fuels. Newer materials come from non-renewable resources and repeated test runs create piles of wasted material. Very few polymers can be recycled and things like powders, resins, and filaments can’t. This creates plastic waste.

The good news is that many 3D printing companies and new material manufacturers are researching renewable materials like bio-based plastics, to work towards a more circular reuse economy.

Knowledge and Skills Gap

Another 3D printing issue manufacturers face is a knowledge and skills gap. 3D printing is still such a new technique that many designers and engineers have not yet learned how to design for it. This means qualified 3D printing technicians are in high demand until the process becomes more established.

Technical education for 3D printing processes isn’t yet embedded in education as it is for traditional manufacturing processes. This will happen eventually and the options are also increasing for upskilling and reskilling employees.

A Maturing Industry

Additive manufacturing has already expanded tremendously since it was invented, both as a technology and a growth industry. Developers are looking now at industrial applications that can fully exploit 3D printing’s capabilities. As it’s an evolving process, it’s important to recognise key trends and monitor their progress. The current trends indicate a maturing industry with huge potential, which still faces many challenges to reach widespread adoption.

Get More From Rowse Straight To Your Inbox