How is 3D Printing Used in the Automotive Industry?

Post By: Ryan King On: 22-12-2023 - Industry 4.0 - Industry Trends - Manufacturing

As we advance into the age of electric vehicles, new technologies continue to drive competition in the global automotive industry. As always, manufacturing companies are racing each other to produce quality vehicles and still make their profits.

An increased emphasis on sustainability makes the competition even more challenging. Automotive manufacturers are being encouraged to incorporate new technologies and techniques. They must also balance agile design processes and sustainability against production costs, efficiency and lean manufacturing principles.

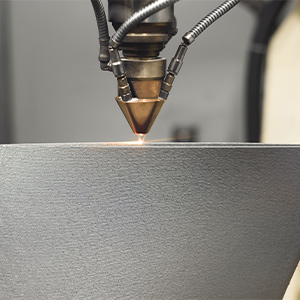

All these are complex facets of industry management and can be challenging to handle effectively. With increasingly tricky automation and digitalisation, it can be hard to deliver products that comply with strict quality requirements while remaining competitive. For this reason, many manufacturers are looking for tools and technology to manage them. One such technological tool that’s helped keep manufacturers on top is 3D printing or additive manufacturing.

3D printing is a vital tool representing a significant technological advantage to production. It allows manufacturers to develop, improve and ultimately reinvent the face of automotive manufacturing.

How Is 3D Printing Transforming Automotive Manufacturing?

There are several ways in which 3D printing is helping to change the industrial landscape.

1. Improving The Process

Additive manufacturing allows design engineers to step outside the box of traditional automotive design. They can design and modify complex shapes in combination with CAD modelling – plus input from AR and digital simulation. These shapes were previously too complicated or impossible to contemplate.

3D printing has the added advantage of producing parts that are no longer available through regular channels. In the classic and vintage car sector, obsolete parts are an occupational hazard, involving a long search for spares or costly re-machining. With additive manufacturing, outdated parts can be printed from old design specs or scanned from an existing failed component. 3D printing can, therefore, extend the life of precious historical vehicles.

2. Lightweight Materials

One challenge for the automotive industry has always been to reduce the overall weight of their vehicles, including their parts. 3D printers help to achieve this by developing new and lighter materials, including advanced polymers and engineered composites. New techniques, such as wire-arc technologies or fibre-reinforced extrusion, can also be used to make previously untenable materials viable for 3D printing.

These new materials and techniques result in a significant weight reduction in manufactured vehicles. This provides the bonus of improving fuel efficiency and cutting down on emissions. At the same time, it allows manufacturers to keep ahead of competitors who may not have the advantage of those performance enhancements.

3. Rapid Prototyping

Speed to market has always represented a key business attribute. It can tip the balance between success and failure in many sectors, especially in the automotive industry. Rapid prototyping has become one of the most critical factors in additive manufacturing. Prototyping is an integral part of product lifestyle management, so faster prototyping can reduce the whole life cycle of design and development in automotive production.

Legacy prototyping methods took up a lot of time in the design process. Methods such as injection moulding and CNC machining are expensive, and making several model iterations could be prohibitive. Additive manufacturing doesn’t have this problem. Using 3D printers means you can create a succession of prototypes very rapidly, even in a few hours. Design engineers can make modifications using CAD modelling and computer simulations so that no physical iteration needs to be produced until the kinks have been ironed out.

This allows for quicker testing, faster and more frequent iteration – and much simpler design changes. The expansion in capacity of additive manufacturing assemblies means you can now print anything from minor automotive components to entire vehicle assemblies. Ultimately, this leads to more effective and efficient product development.

4. Increased Efficiency

3D printing is fast and can achieve such precision that you can now manufacture automotive parts on demand. This has several advantages to efficiency, apart from the speed-to-market element noted above. 3D printing is a much more self-sufficient process, especially if you can do it in-house. This means you can reduce or even eliminate the risk of running out of stock. You can maintain the leanest possible inventory with no need to carry extensive stocks of spare parts.

5. Customised 3D Printed Parts

One of the most significant benefits of 3D printing is its potential for customisation, an essential factor in automotive manufacturing. Traditional manufacturing methods of outsourcing custom design used to cost more and have an extended lead time. Additive manufacturing enables the production of design modifications that are not feasible using these legacy methods.

Customers can also commission custom-tailored parts to their specifications instead of choosing from manufacturers' off-the-shelf components. Individually tailored components such as lug nuts or heat exchangers can be customised quickly and efficiently to prevent theft or improve performance. They also introduce a new range of possibilities for creating customised features like dashboards, seats or specialised modifications for people with disabilities.

6. Sustainability

The automotive industry has always sought to manufacture with the most excellent possible efficiency, but traditional processes like machining produce lots of material waste. 3D printers make such objectives more achievable since they build up materials rather than cut them down. More environmentally friendly materials are also being incorporated, using less energy and producing less waste.

Why Use 3D Printing In The Automotive Industry?

3D printers promote greater agility in the development and production process. It’s more cost-effective and time-saving than legacy production methods. This means manufacturers can focus on improved performance, crafting, and customisation. The availability of different materials in additive technology also empowers automotive manufacturers to expand on traditional manufacturing methods to produce innovative new vehicles.

The versatility and flexibility of 3D printing help automotive manufacturers reduce waste, making production more energy-efficient and sustainable. Manufacturers can shrink their carbon footprint, which represents a goal for almost every automotive company today.

Get More From Rowse Straight To Your Inbox