3D Printing Trends

Post By: Ryan King On: 11-01-2023 - Industry 4.0 - Industry Trends - Manufacturing

3D printing has made huge advances in the last 40 years. Officially known as additive manufacturing (AM), this technology starts out with a digital 3D model – hence its more common name. From this model, 3D objects can be constructed by adding physical materials according to the design specification. As opposed to, say, a machine cutting out or grinding down materials to the required size and shape, 3D printing builds them up. It’s a much more cost-efficient method of production, as nothing is wasted.

The first industrial uses of 3D printing technology were producing prototypes of a specialised item, or parts in very small batches. While this aspect of 3D printing is still important to industry, its major focus has evolved. 21st-century AM is more interested in the end-use production of new and innovative solutions. Industries like health, energy, automotive and aerospace are looking for more efficient and higher-performing parts. The process is also being incorporated into other manufacturing processes, creating hybrid techniques for conventional processes like injection moulding.

3D Printing Trends

3D printing has reached a point where it’s likely to be industrialised on a large scale. As the technology evolves, it’s important to take stock of its developments and direction. Some key trends outline the current industrial uses of 3D printing, and what its manufacturers and users hope to do with it in the future. These key trends include:

Bringing 3D Printing In-House

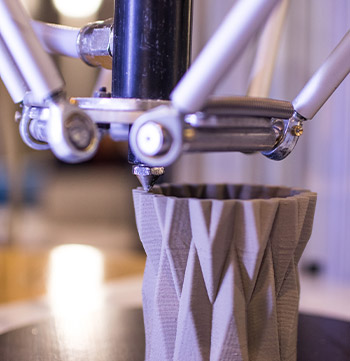

Rapid prototyping is still one of 3D printing’s most widespread uses. No other technology can match its ability to produce high-quality prototypes, quickly and cost-efficiently. These can serve both visual and functional purposes, like testing and evaluation. Using an in-house 3D printer enables product designers and engineers to generate prototypes from 3D models. You can then comprehensively evaluate and test these prototypes, easily integrating changes and quickly printing new iterations.

With the agility of 3D printing, your product development methods will be transformed. In-house prototyping can dramatically reduce your production lead times. At the same time, you know that your engineers have modified the design continuously until they’ve achieved the best possible part design. You’ll also save time previously wasted in waiting for third-party manufacturers and shipping.

Stronger Focus on Designing/Printing Spare Parts

Using 3D printing, you can leverage digital inventories to print spare parts on demand. You no longer need to order and store replacement parts, but simply print them when and where you need them. In addition, you can also replicate rare or obsolete parts, without any necessity to invest in costly tooling. 3D printing will revolutionise your spare parts production, cutting down or entirely eliminating inventory and warehousing costs, long lead times and complex logistics.

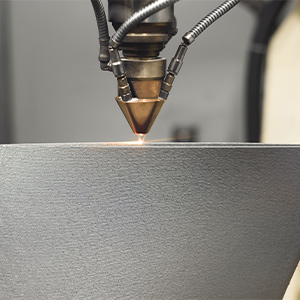

3D printing is also opening up a lot of new industrial applications with its ability to use new and diverse materials. It’s no longer confined to the low-grade plastics that were appropriate for prototyping, You can now expand production viability and versatility with 3D printing of metals, ceramics, industrial-grade plastics, alloys and composites. These materials are critical to discovering new high-performance applications, as they are continuously being developed for specific AM processes.

Using 3D Printing With Other Manufacturing Techniques (Hybrid Manufacturing)

As the technology matures, many manufacturers are beginning to recognise the benefits of combining 3D printing with conventional methods. Each can complement the other, to enhance the overall efficiency of the production process. For example, you can hybridise traditional manufacturing processes like machining with 3D printing. One way is to print your near-net-shape parts, and finish them off with CNC machining to achieve tight tolerances.

Another innovative hybrid is found in injection moulding, by printing a 3D mould in a soluble material. Once the prototype has been injected and set into the mould, the printed material dissolves, leaving just the finished item. In this way, you can combine the benefits of the two processes into a single, more efficient hybrid. Injection moulding offers high quality, material versatility and minimal post-processing. 3D printing offers greater cost efficiency and design freedom for small-scale production.

Improvements In Speed And Accuracy

The main advantage of AM is that you don’t need any tooling – but 3D printing speed is still an issue. Although it’s usually faster to print a single unit or small batch than making them by traditional methods, the same doesn’t apply for larger-scale operations. Once you start scaling up production volumes, the time it takes for printing is a negative factor. However, system developers are working to improve build times by optimising printing parameters. This means they’re tackling issues like printhead or laser speed, plus altering stacking and print bed orientations. They’re also introducing more automation to post-processing steps, which in the past have been mostly completed by hand. This not only makes them much faster, but more efficient.

In the past, there has also been some discrepancy in the specifications laid down in the CAD model and the printed result. This is largely because the pinpoint accuracy of the design measurements couldn’t always be materially replicated, particularly on curved surfaces. Advances in AM research have altered the approach to incorporate options like variable layering, to accommodate different material thicknesses. Programmable robots can also prescribe and measure the accuracy of the printing while it’s in progress, and make alterations to correct errors as they occur. A similar idea is Warp-Adapted-Modelling (WAM), which uses data from an initial prototype to identify errors before producing an amended model.

New Materials And Applications

3D printing has expanded considerably since its invention in the 1980s, both in its technologies and its applications. Industry focus today is increasingly on applications that really exploit its capabilities. AM is moving into an area where even large items like bridges and houses can be printed, using fibre-reinforced extrusion or wire-arc technologies. Innovative new materials are being discovered and adapted to the method, and accuracy and speed are improving.

Get More From Rowse Straight To Your Inbox