How To Choose The Right Air Hose

Post By: Tom Rowse On: 30-06-2020 - Pneumatics

A hose is a hose, isn't it? Well, from our experience at Rowse, we would say no – not necessarily. Hoses are more complicated than you might think, and knowing how to choose the right air hose depends on several important factors.

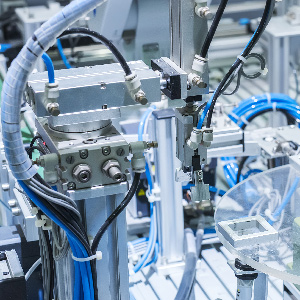

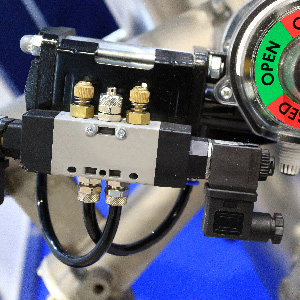

To transport air from the compressor to a pneumatic application, you will need to consider the hose dimensions, the material from which it's constructed, and its function. The dimensions of a hose include its overall length and its ID, or internal diameter. The hose itself can be constructed in a variety of materials, which will in turn be influenced by the environment in which it'll be used.

Length

Air hoses are commonly supplied in a choice of lengths, and it's possible to get many different lengths of hose for various types of application. The length you choose is dependent on the distance you need to cover between the compressor and the workspace of the pneumatic tool. A long hose will allow a greater separation between the workspace and the compressor, but some of the air pressure will be lost in transmission. A shorter hose is more manoeuvrable in tight spaces, maintains pressure better, and works well with a portable compressor.

When deciding how to choose the right air hose, a lot depends on the manoeuvrability of the pneumatic tool and the size of your workspace. Shifting the compressor may be simpler than trailing a long length of hose. However, if your application requires you to move around a lot, such as using a spray gun in a body shop, then a longer hose will be needed. A shorter hose can always be extended by supplementary hoses and couplers, although you should expect to experience small pressure drops where couplers are used.

Internal Diameter

The ID of the hose is important in determining the rate at which the compressed air can be supplied, with the most common IDs being 6mm, 8mm and 10mm. The greater the diameter, the more litres per minute (l/min) of air can be supplied to the pneumatic tool. On the other hand, a larger bore will also add significantly to the weight of the hose, and make it less manoeuvrable.

You should calculate how many l/min of air your application will require. Then choose the corresponding ID necessary to supply that air, and maintain its pressure over the distance travelled. The higher the l/min, the bigger the ID that you'll need, with most hand-held tools using a 6mm hose, and more heavy-duty applications needing an 8mm or 10mm. If your pneumatic tool has the same l/min requirement as the output of your compressor, you should use a shorter, wider hose to minimise loss of air pressure through friction.

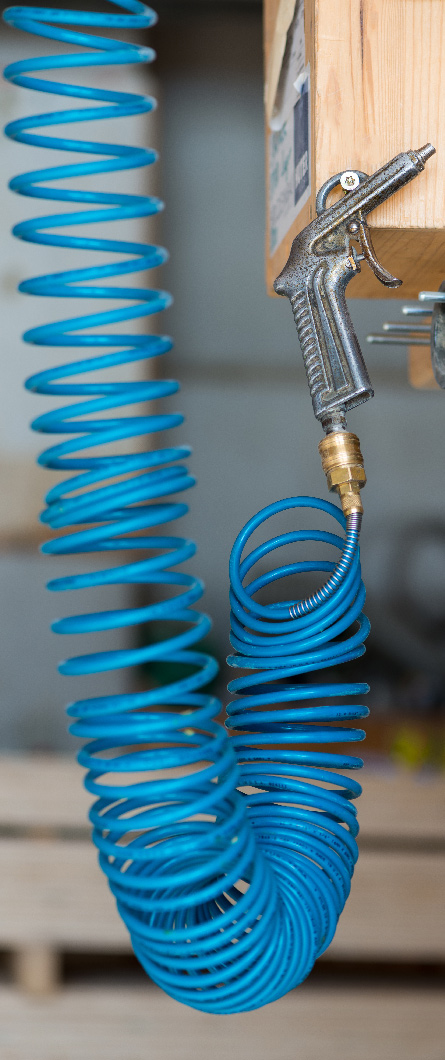

Straight or Curly?

Choosing the right air hose also involves the choice of a standard, straight hose or a curly, recoil one. Standard hoses lie flat, without coils or bends, but they can get kinks in them which reduce or cut off the air supply. On the other hand, they're easy to handle, offer no resistance and can be gathered up into loops for storage or mounted on a hose reel. Curly or recoil hoses are like old-fashioned telephone cables, with a lot of small, regular coils making them seem much shorter than they actually are. These coils are highly tensile, and spring back in place after use, as they are designed with a memory. They are easy to store and to keep out of the way when not in use, but they offer resistance and require some strength to stretch them out, particularly if they're long or have a large l/min.

Materials

Modern air hoses come in a wide variety of synthetic materials, which have largely replaced the older styles of rubber hose. Lightweight materials can be reinforced with braided steel wire or fibre layers. These give the hoses great strength and resistance, while allowing them to remain very flexible. Deciding how to choose the right air hose material will depend on its function and place of use, particularly if your application is to be in a hazardous or extreme environment.

Polyurethane is a thermoplastic material similar to PVC, which is often considered a good general-purpose hose material. It's a lightweight, abrasion-resistant option, with a surprisingly long life, and remains flexible in a wide range of working temperatures. It's more flexible than PVC and lighter than rubber, but is prone to kinking. This material is a good choice for more mobile applications.

Nylon hose is generally lightweight and easy to store, while being resistant to abrasion and good for high-pressure applications. Nylon hosing has low permeability coupled with excellent dimensional stability, but it kinks easily and doesn't last as long as more durable options.

Neoprene is a very lightweight form of synthetic rubber, which makes for a highly flexible hose. It's capable of great precision in the work area, in pressures up to 200 psi, and can resist both heat and cold.

EPDM is another form of synthetic rubber hose used in industrial, agricultural and construction applications. EPDM offers a high resistance to both heat and cold, and great flexibility even at low temperatures. Hoses made of this material are weather and ozone-resistant, so they're good for outdoor applications, as well as being mildly resistant to chemicals.

Thermoplastic hoses are generally constructed of various polymers such as polyurethane or PVC, and bonded and reinforced with a layer of braided steel or fibres. They're extremely resistant to extremes of climate or environment, and have a low expansion rate. The strength of bonded thermoplastic hoses makes them popular for use in rigorous industrial applications.

For safety reasons, you must choose a hose with a maximum working pressure that's greater than that of your pneumatic application. This means you should check the pressure at which your application operates, correlate it with the correct l/min, and select your hose based on the highest potential pressure of the piping system. We recommend you double-check the specifications of all parts of the system before choosing a specific hose.

Get More From Rowse Straight To Your Inbox