What Is A Digital Shipyard?

Post By: Tom Rowse On: 27-04-2021 - Industry 4.0 - Industry Trends - Manufacturing - Military

"Digital shipyard" is the term applied to the adoption of Industry 4.0 capabilities in designing, building, maintaining our ships and submarines as well as using this technology to monitor and maintain the associated infrastructure.

Digital shipyards utilise the Industry 4.0 capabilities of "Cyber-Physical Systems" (CPS) and Internet of Things (IoT) to evolve shipyards for the modern era. The sensors and monitoring systems deployed by CPS can communicate enormous quantities of data to an IoT device, providing an enhanced capacity for predicting and planning future maintenance. This greatly reduces operational downtime. The collected data can be shared with other IoT devices in an industrial environment, collectively called the Industrial IoT, or IIoT. Having a connected shipyard can reduce maintenance costs through Predictive Maintenance, energy monitoring for improved efficiencies.

Additionally a Digital Shipyard also has benefits in the design stage of a build, ocean-going ships and submarines are physically large, with design models and mock-ups being expensive and time-consuming. By combining the Internet of Things (IoT) with cyber-physical systems (CPS), shipbuilders can produce virtual models in a fraction of the time. These are used to test, modify and improve designs before physical production commences.

Not only does this provide a much safer testing environment, but it also saves vast amounts of energy and resources that would otherwise be wasted in producing physical models.

What IIoT Systems Are Used In A Digital Shipyard?

Several IIoT and emerging technologies are contributing to the rise of the digital shipyard. They can be roughly divided into three categories: the production or building phase; the servicing or maintenance phase; and the delivery or control phase. The benefit of deploying these technologies in the digital shipyard is to reduce overall production time, and to improve the overall quality, reliability and safety of the end product.

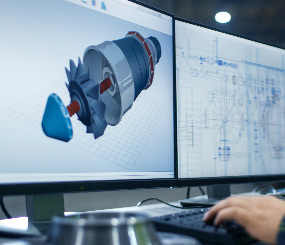

3D Modelling

3D modelling isn't new, but advances in computing mean it's now being used a lot more in manufacturing. Shipbuilders have previously used it to enhance existing 2D designs, but 3D scanning technology now means that 3D models can be created from existing ships. 3D modelling is an important advance for a digital shipyard because it enables performance simulations across all three dimensions. Designers can see how specific designs work for particular activities and what modifications are required. This is particularly useful in spatial calculations, to see if items fit in the space assigned to them, and whether they can easily be moved into and out of the entry point. Designers can then determine whether a compartment needs to be redesigned or the entry point widened.

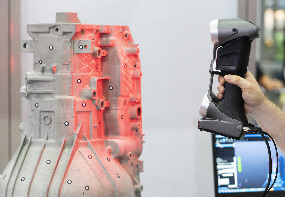

3D Scanning

3D scanning creates a digital version of an existing object, creating a clone or digital twin, so that models no longer have to be worked up from 2D diagrams. The technology relies on advanced optics and lasers to map out the physical environment, and can be very useful for retroactive modelling. The model is then used as a digital twin to run engineering simulations and modifications. Scanned images can also be compared to original design specs, to ensure there is no disparity in the dimensions. If any disparity is found, it indicates an issue with the actual construction.

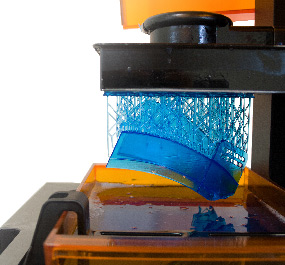

3D Printing

3D printing or additive manufacturing means that any object that can be digitally modelled in 3D can be uploaded and printed. It's been possible for some time to print small parts in plastics, but recent technological advances are enabling larger printers to create much bigger components. Some of these new systems can also create parts out of metal, using a technique of high-velocity particle fusion.

This is an important development for the digital shipyard, because it means that parts can be printed on site, during the initial build or service phases. There'll be no more waiting while replacements are ordered for damaged parts, thus considerably reducing repair times. Provided a digital twin such as a CAD model is available, any part can be quickly and easily produced.

Digital Twins

A digital twin is a 3D model that can simulate the physical characteristics and operational dynamics of its physical counterpart. This is particularly useful in a digital shipyard because of the large size and scale of the processes involved. Digital simulation can help resolve design issues such as line of sight, emergency evacuation routes, storage and transportation, and compartment sealing if there's a hull breach.

Digital twinning enables design engineers to predict and simulate potential design faults in a safe environment, long before any physical construction takes place. This dramatically cuts down the time and labour of the physical build, eliminating much of the retroactive snagging that used to be necessary.

The UK-based aerospace and defence company, Babcock International, are collaborating with BAE Systems to implement and develop digital twinning in their defence technology. In this way, Babcock are able to optimise the availability and overall performance of their weapons systems, and extend their service life.

AI/ML

Artificial Intelligence (AI) is essentially the ability of machines to think for themselves, and to perform the same tasks as a human being. With advanced sensory equipment, AI can replicate perception of sights and sounds, including speech recognition and spatial awareness. It can then go on to make independent decisions. This is enhanced by Machine Learning (ML), giving machines access to quantities of data from which they extrapolate information and learn.

This is useful in a digital shipyard where smart applications can be supplied with design parameters and expected goals, including materials and costs. An AI system computes these parameters to produce an optimal layout for the desired design goals. This system is further enhanced with ML, which uses its intelligence to combine existing data with optimal design layouts and previous builds, to produce a best-case design scenario.

AI can power a digital twin model simulation, and overlay it with a smart application that will learn from the simulation in real time as it's running. In large-scale design operations such as shipbuilding, the ability to do this digitally saves enormously on time, materials and labour.

AR/VR

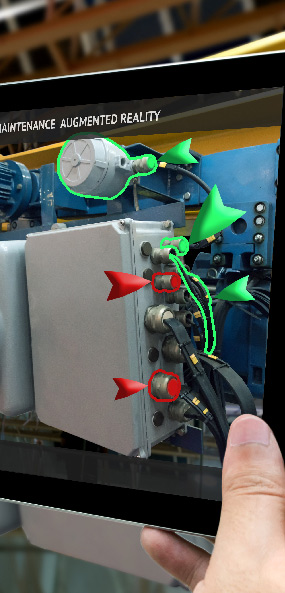

Augmented Reality (AR) provides the user with a digital overlay to the real world, so that a person wearing an AR headset can physically walk around a vessel and see the relevant schematics and other information en route. Instead of having to print the information and carry it to the ship, sometimes making several journeys if alterations are required, AR permits the user to access all necessary information on site. This will greatly simplify and speed up the vessel's construction and maintenance phases.

When walking around a structure as complicated as a ship, it's particularly important to do this safely and not bang into things while poring over your tablet. Drawings are preloaded instead onto AR headsets, which can even be directly connected to a project life-cycle management system to access schematics, videos or other necessary media. A drawing can be loaded into the user's virtual landscape, and then digitally pinned to the physical landscape observed by the user. Loading video maintenance guides to the headset greatly simplifies a technician's service routines.

Virtual Reality is used in the digital shipyard to provide an immersive virtual design environment. 3D design and scans are combined to create a digital twin of a vessel or compartment, where a user with a VR headset can just step in and experience the design virtually. This capability is particularly important in a digital shipyard, because its size and structural scope allow designers a much deeper understanding of the vessel before it is built.

Instead of attempting to visualise a model from a paper or CAD image, VR allows design engineers to walk around and simulate tasks inside the ship itself. Users can also assess potential interferences and alter design elements using their own hands, while still within the virtual landscape. Further advancements in VR technologies allow for dispersed collaboration among participants, so that design engineers in different geographical locations can consult in real time within the virtual environment. This considerably speeds up the peer review and design process.

IIoT

Combining the communication ability of the IoT with big data and machine learning, the digital shipyard uses the IIoT to improve its manufacturing processes and expedite decision making. Big data from sensory input comes from critical metrics relating to tools and equipment that measure operational efficiency, such as time on tools, throughput, quality, yield, downtime, and more. ML can help analyse this data, to identify and reduce time-wasting bottlenecks.

It's possible, for example, to determine how much welding material is used for any given task, by using sensors embedded in the welding equipment. Sensors can also be embedded for safety purposes in wearable accessories such as helmets or watches. These can measure such factors as the number of steps taken, height above ground level, or the wearer’s heart rate or temperature. IIoT-enabled RFID tracking could also be used on dangerous machinery to ensure that the user is certified to use it.

High-Performance Computing (HPC)

The concept of a digital shipyard is to enhance operational efficiency and effectiveness, using technology to achieve smarter, faster and safer performance. HPC simply means ramping up your computing power to produce dramatic increases in speed, with knock-on impacts on scheduling and costs.

HPC usually uses the greater computing resources available from the web server or cloud, rather than data stored on clients' desktops or PCs. HPC is particularly valuable in the digital shipyard for the kind of complex high-end graphic demands of digital design and VR simulation. AI also becomes exponentially faster and smarter with HPC. Even now, a ship design typically has 1,800 or more stored digital models. These can now be easily shared with thousands of design engineers and suppliers.

Robotics

When you apply AI to repetitive processes you get Robotic Process Automation (RPA). Software robots, or bots, are programs that analyse how a human interfaces with an existing computer process. The bot then assimilates this interaction, breaks it down into machine algorithms, and repeats the process by itself. ML also factors in a human being's diversity of choices, based on prescribed parameters or experienced events. It incorporates these into its learning process, so a bot can replicate repetitive human tasks more quickly and efficiently. RPA is valuable in the digital shipyard because it frees human beings from monotonous or inefficient tasks, letting them concentrate on more useful work.

Blockchain

Blockchain enables a greater degree of security within collaborative program environments like the digital shipyard. Design engineers, suppliers and stakeholders can centralise their collaborative activities on a single, secure platform. This means that people across the world working together on a program no longer need to worry about data leaks via email, web portals or other insecure communication links.

Using blockchain, a collaborative data-centric program environment is completely integrated, so all relevant information is created and managed in a single secure space. All required applications are located there, so no data needs to be routed through an external source. The user enters the virtual environment through a secure portal and runs the applications inside it, to collaborate securely with others and perform necessary tasks.

All the source data on a blockchain is kept encrypted by its secure environment, with each party to the collaboration holding an exclusive encryption key. Instead of having to encrypt all the separate data files such as presentations, password-protected spec sheets or layouts, the encryption encapsulates the whole secure software environment. The level of encryption offered by blockchain provides strong protection against alteration, destruction, theft, or even accidental loss of valuable data.

Its fundamental benefit is that it provides a trackable, multi-level, compartmentalised protection for all your data assets. This helps to foster team spirit and eliminate working boundaries, improving collaboration while still keeping sensitive data secure. Professional productivity is enhanced when people are no longer afraid that sensitive information might be lost, stolen, contaminated or destroyed while collaborating with outside partners.

Blockchain has also had a considerable impact on procurement and traditional supply chain management. A supply chain tower (SCT) with AI and ML can independently research and identify alternative providers of parts and services, in order to get the best value and quality. In the digital shipyard, the supply chain procures over 60% of most ship’s components, so this technology can reduce the effort and cost of finding alternative suppliers. It takes into account not only costs, but also reliability and safety records, before putting forward a suggestion for switching suppliers.

Benefits Of The Digital Shipyard

Many major shipbuilders in the commercial and defence sectors are adopting a combination of Industry 4.0 technologies to create a “Digital Shipyard” for the future.

The benefits of the digital shipyard are not limited simply to space-saving convenience, as it also delivers great advantages in the day-to-day operations of the design and shipbuilding team. They are simultaneously reducing modelling costs, and the time that used to be spent building prototypes. Industry 4.0 technology increases both their safety and design efficiency.

Utilising a combination of AR/VR techniques with AI and ML helps to minimise downtime, and enables the prediction and planning of future maintenance. 3D scanning, printing and modelling make the design and repair process faster and more efficient. And of course, the digital shipyard provides substantial savings in energy consumption.

Get More From Rowse Straight To Your Inbox