The Role of AI in Sustainable Manufacturing

Post By: Tom Rowse On: 27-03-2023 - Industry 4.0 - Industry Trends - Manufacturing

The concept of sustainable manufacturing is based on several key features:

- Reducing energy consumption

- Using natural resources efficiently

- Minimising waste

The overall goals are to minimise the environmental damage caused by industrial production, and, more specifically, to do our best to reduce our industrial carbon footprint. There are several ways to modify our manufacturing processes to achieve this, including a move towards a more circular economy and switching to renewable energies. An approach which can also help is to harness the capabilities of artificial intelligence.

How Can AI Help Promote Sustainable Manufacturing?

Industry 4.0 has brought with it many technologies that contribute to the goals of sustainability. These include automation, sensor technology, IIoT and wireless connectivity. Using these technological tools, industry can now generate, collect, track and analyse the vast amounts of data that are the basis of AI initiatives. This data can usefully be harnessed to support the business and sustainability objectives of today’s manufacturers.

These objectives include:

- Enhanced product design

- Optimised production planning and logistics

- Predictive maintenance

- Improved quality and process control

- Agile robots

- Energy efficiency

- Minimal waste

A combination of advanced sensory equipment and computer vision allows AI to receive and process a huge spectrum of information. The vast amount of data can be analysed in a fraction of the time it would take for human analysis. Machine learning (ML) and natural language processing (NLP) enhance the information to produce a more coherent and streamlined outcome. The role of AI in sustainable manufacturing is therefore an increasingly important one.

Enhanced Product Design

Advances in virtual reality and computer-aided design (CAD) have led to the phenomenon known as digital twinning. Making digital twins can greatly enhance product design in many industries, particularly with large-scale items like cars and ships. Using this technique, design engineers no longer need to build complete product prototypes for testing. Instead, they use CAD tools to create digital twins, which they then manipulate through virtual or augmented reality. Making changes to specifications is vastly simplified. There is no requirement for space to build scale models, and no actual materials are wasted. Manufacturing costs are significantly lowered, a great deal of time is saved and energy use is reduced.

Optimised Production Planning and Logistics

The combined tools of AI and the IIoT will help to optimise decision-making in every area of a business. The IIoT network collects data constantly – about product status, inventory, logistics, distribution, and more. Since the network extends outside the business itself, it can also incorporate information about business trends, real-time market information, point-of-sale figures, and even the weather. AI tools combine and analyse this big data, and then apply predictive analytics and ML to produce actionable insights. This allows much more accuracy in production planning, and more precise logistics.

Predictive Maintenance

Predictive maintenance aims to eliminate equipment failures that cause production delays or dangerous emissions. Using AI’s capabilities to analyse the causes and extent of machine downtime produces data that can be applied to eradicate them. Measures can be applied like checking for leaks in compressed air systems, and replacing components before they’re predicted to fail. Unscheduled machine failures will become rare and equipment more reliable, saving both energy resources and maintenance downtime.

Improved Quality and Process Control

The range of AI capabilities allows a much closer analysis of manufacturing processes, which helps to identify avenues of improvement. AI analysis of data relating to material failures can help identify their cause, and lead to amendments in production techniques that would eradicate faults. Big data analysis of items that have failed quality control can show patterns in manufacturing processes. ML is able to process such patterns and help quality controllers figure out the root causes of material failures.

Once this data has been effectively applied, business owners can then introduce a data management platform. This would give production employees access to both stored and streamed data, allowing them to track information and act on it in real time. If the whole organisation is adapted to support AI initiatives, IT experts can work with specialists from other parts of the business to form a combined manufacturing strategy.

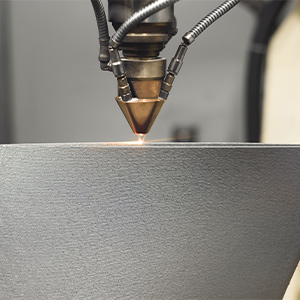

Agile Robots

There are already a substantial number of systems that operate with robots. These range from the fully automated factory to robotic arms and self-propelling vehicles. The advantages of using robots include round-the-clock production, which in turn enables lights-out manufacturing. They also offer much greater safety, especially in operations which might be hazardous to human health. They can operate in extreme conditions and are far more robust, being capable of both heavy lifting and extremely delicate, precision motion.

Add AI to all this, and you have machines that can self-regulate and adapt to circumstances. These robots can walk and even run, and can alter their configuration to fit in with their environment or the requirements of any particular task. In manufacturing, agility in robots means that they can identify production or process failures, and automatically recover the process, and themselves, from those failures.

Energy Efficiency

AI sensory and monitoring systems can help reduce energy and lighting demands. For example, they can regulate the amount of heat or light in a room by tracking the number of people in it. If there’s no one there, lights go off automatically. Intelligent systems can also support fully automated production facilities, and operate on a lights-out basis to maximise efficiency. Businesses can increase energy efficiency by investing in renewable and low-carbon energy systems, which can be managed by AI.

Minimal Waste

AI can help reduce waste in a number of ways, starting with predictive maintenance and intelligent supply chain management. It can programme materials for recycling, reuse heat, and minimise energy losses from constant heating and cooling. Businesses can also implement the principles of lean manufacturing, which are based on eliminating waste.

AI and Sustainability

It’s still early days in the widespread acceptance of AI, and in understanding how much it can do to support sustainability. However, the rise of Industry 4.0 has already demonstrated the potential benefits this technology could offer. Using AI to achieve both business and sustainability objectives makes economic and environmental sense.

Get More From Rowse Straight To Your Inbox